Tungsten Carbide

Tungsten Carbide Specialization

Tungsten carbide is one of the hardest materials on earth, according to the Mohs Hardness Scale, the compound ranks above 8 on the qualitative scale. This is why the earthmoving industry and those involved in drilling and mining rely on different components made from tungsten carbide to get the job done, even in the most challenging situations.

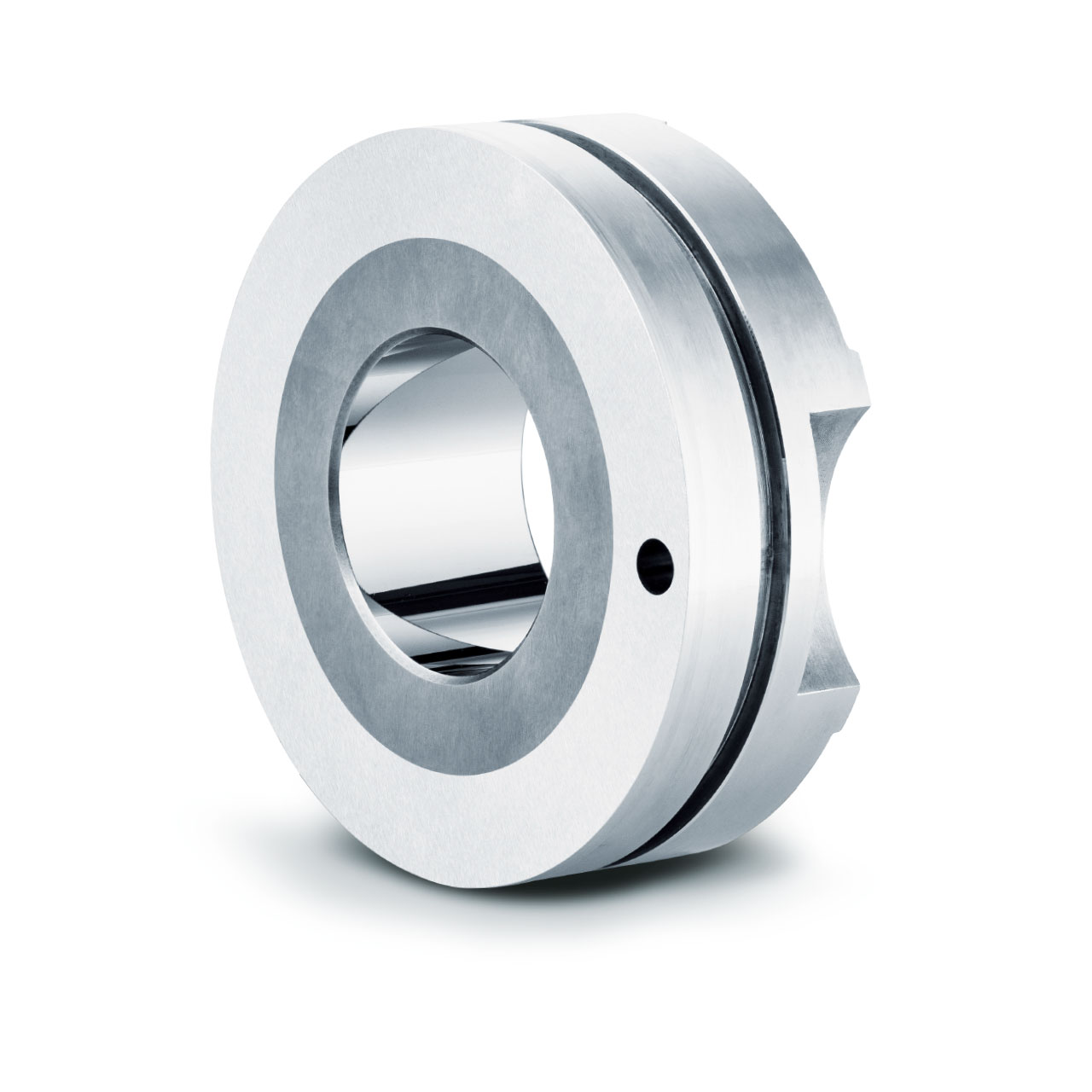

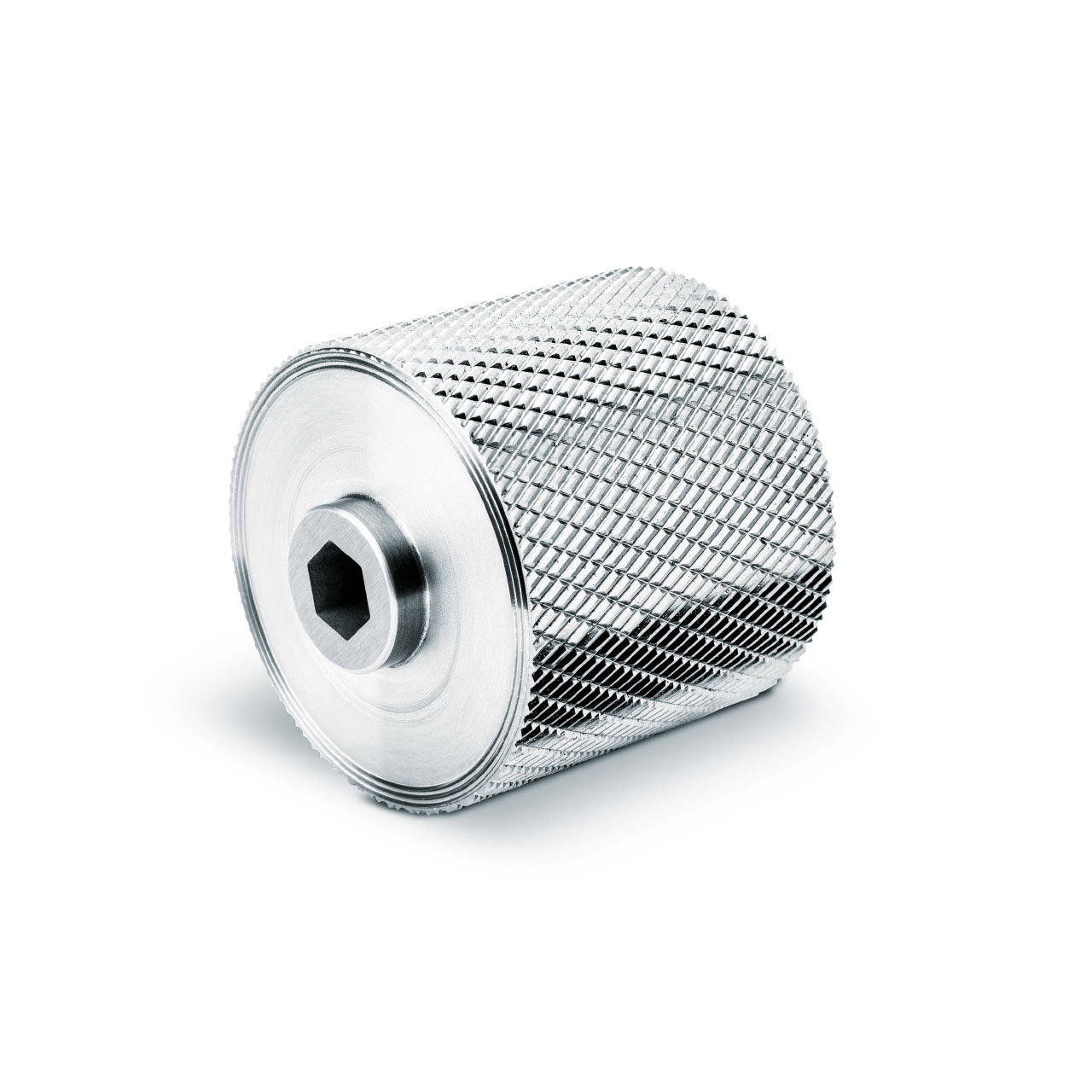

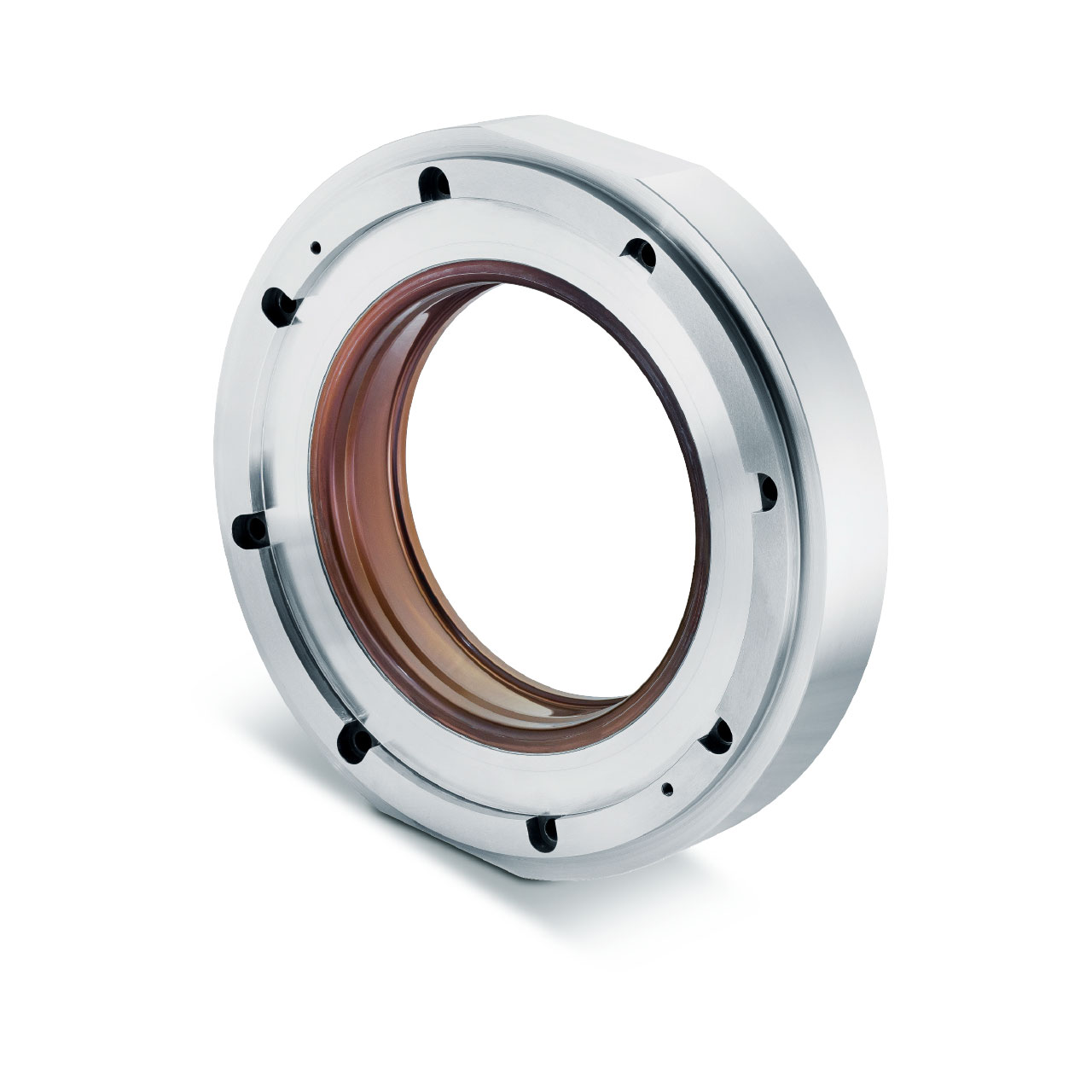

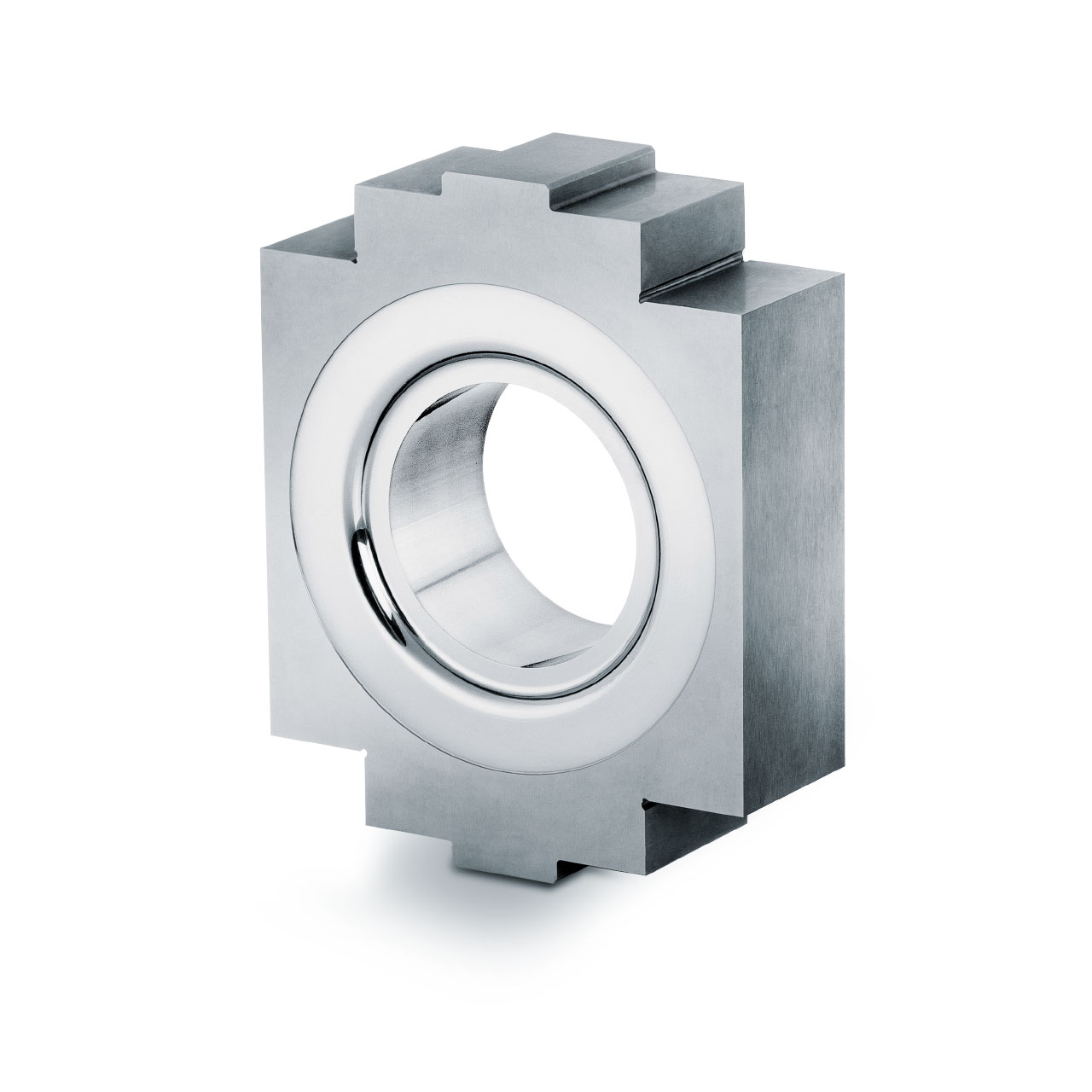

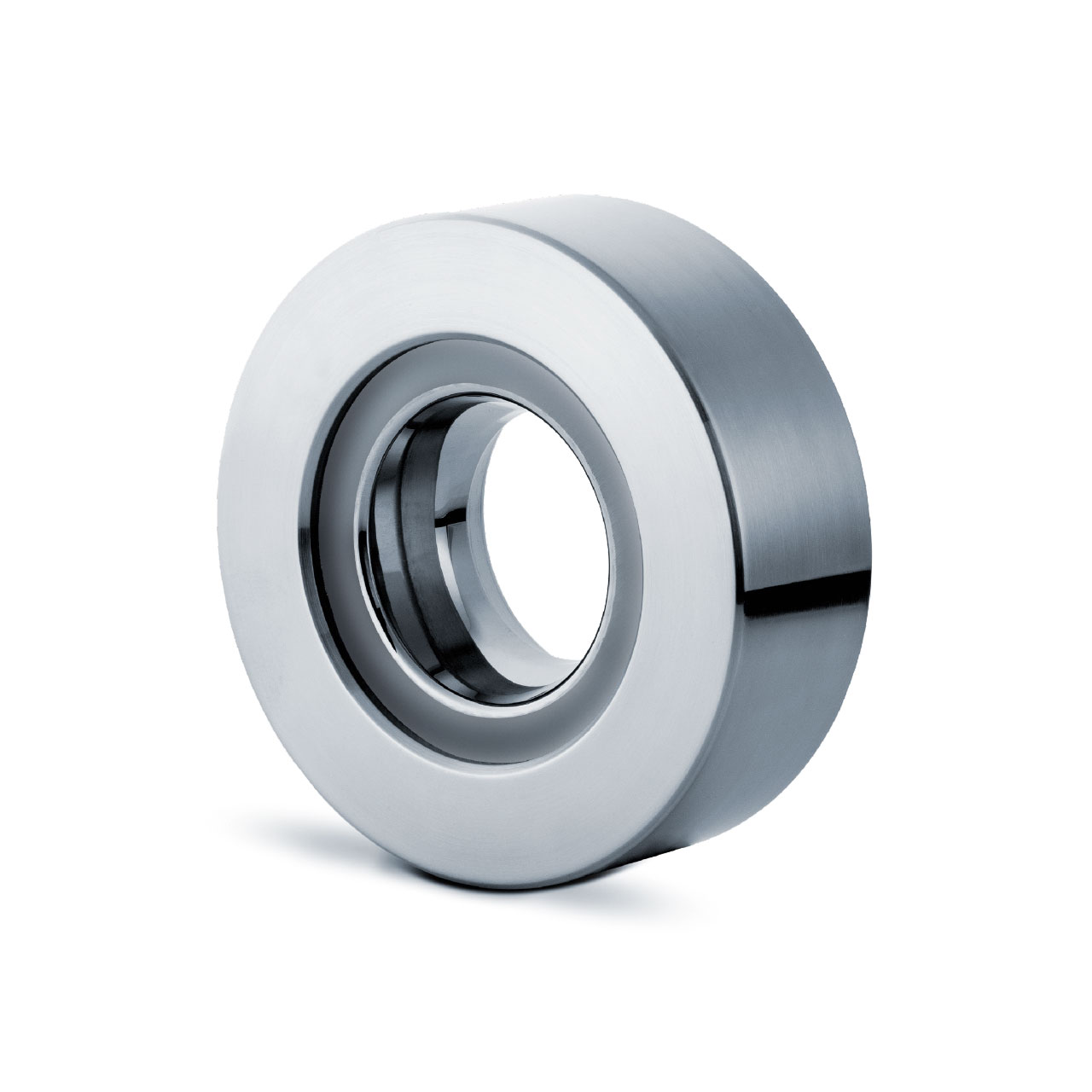

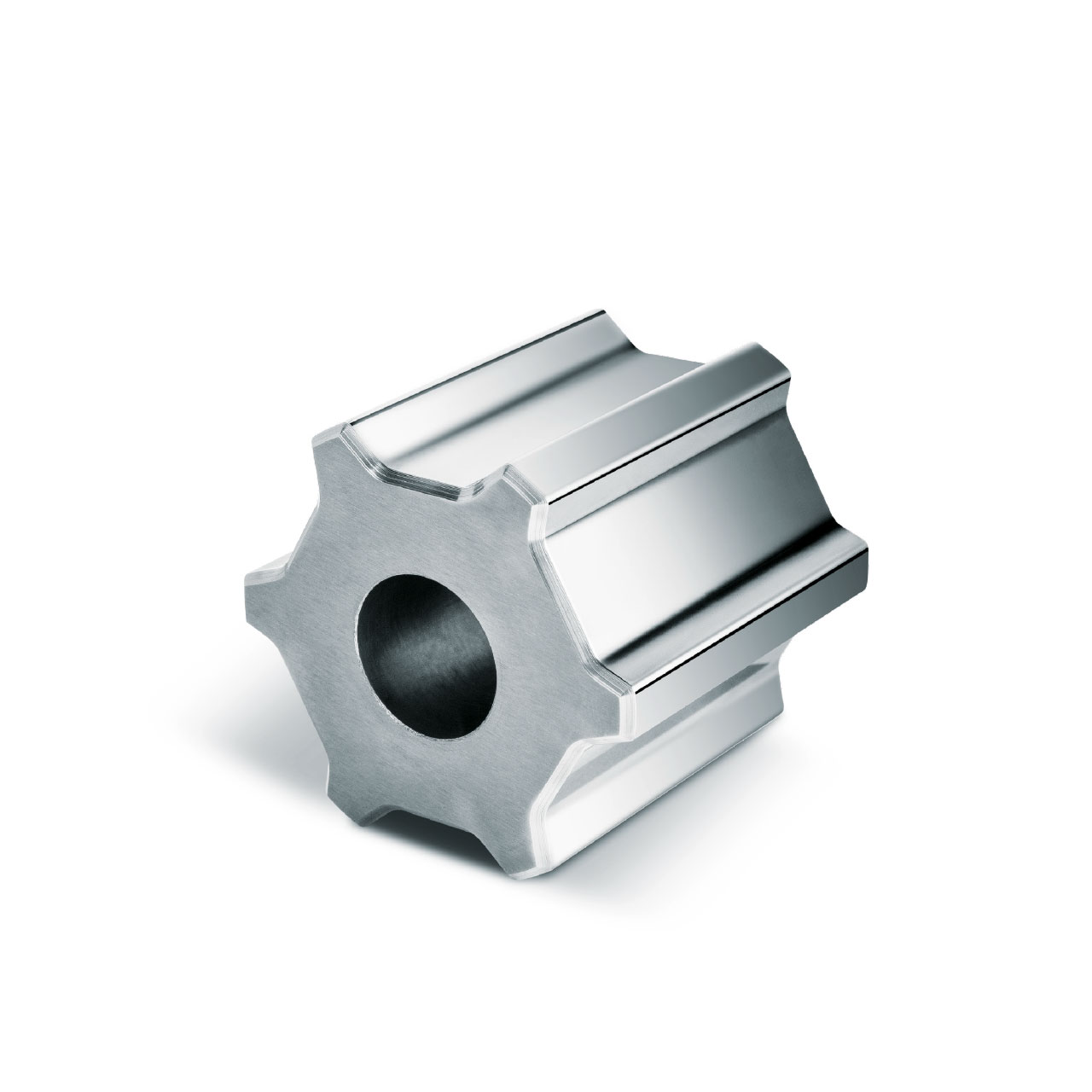

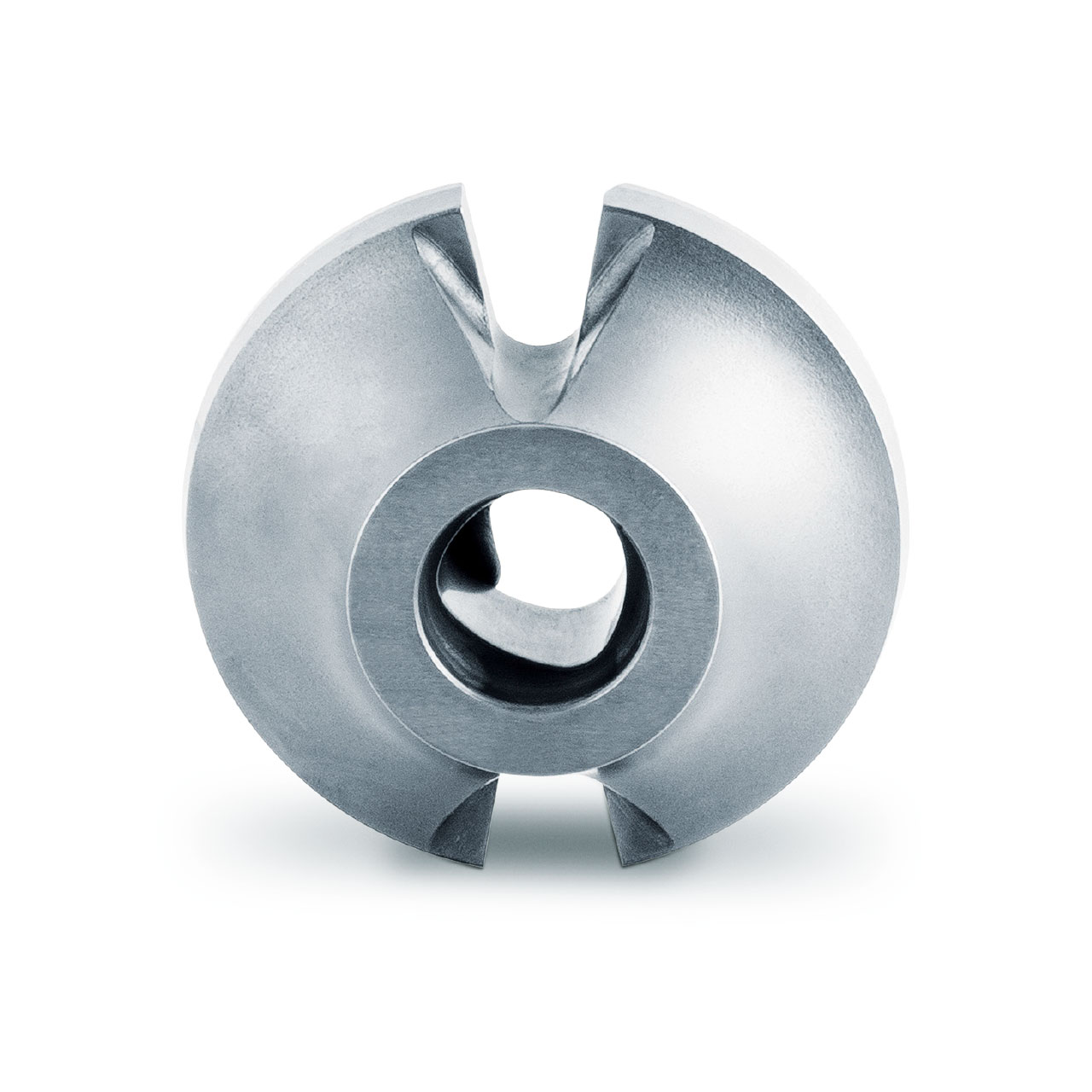

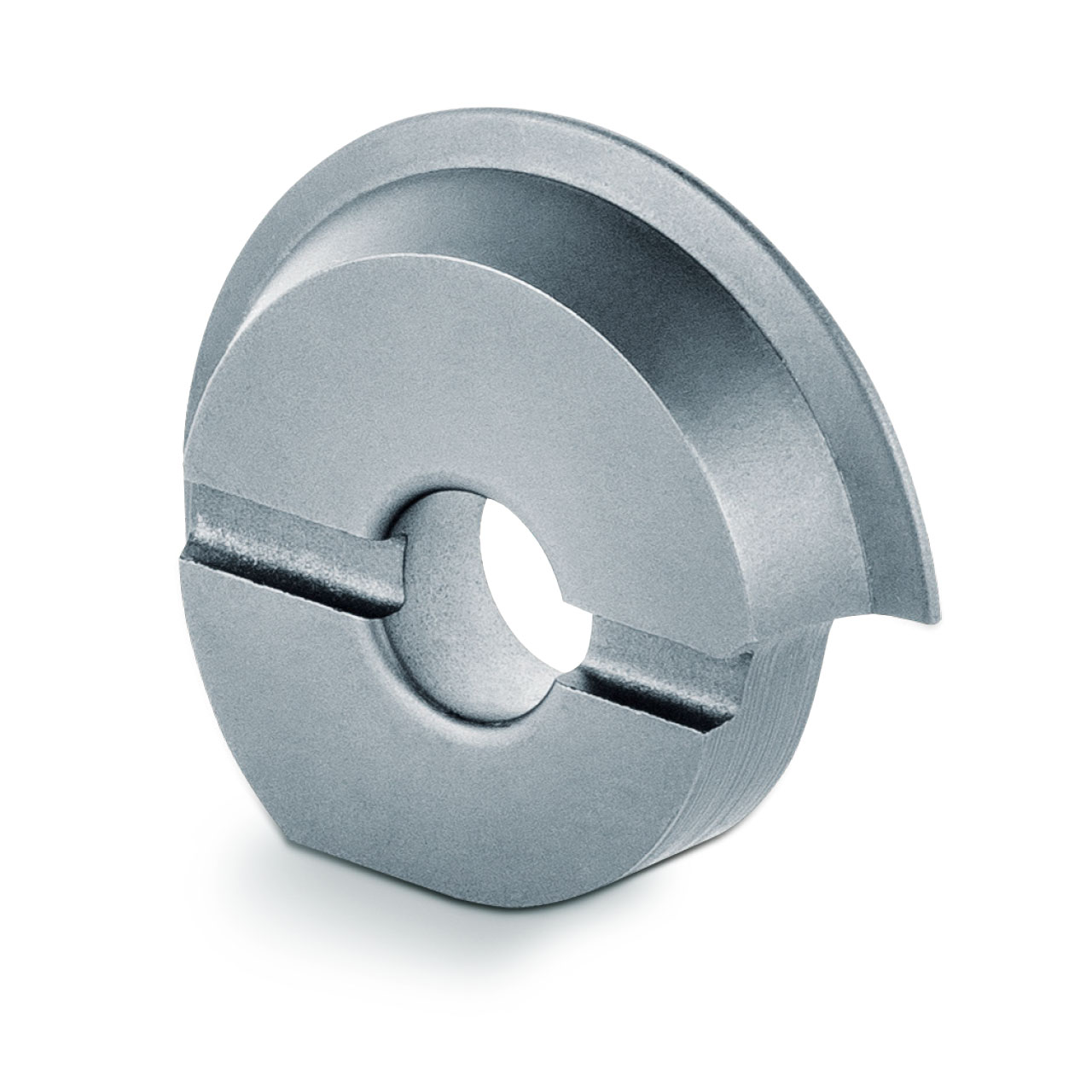

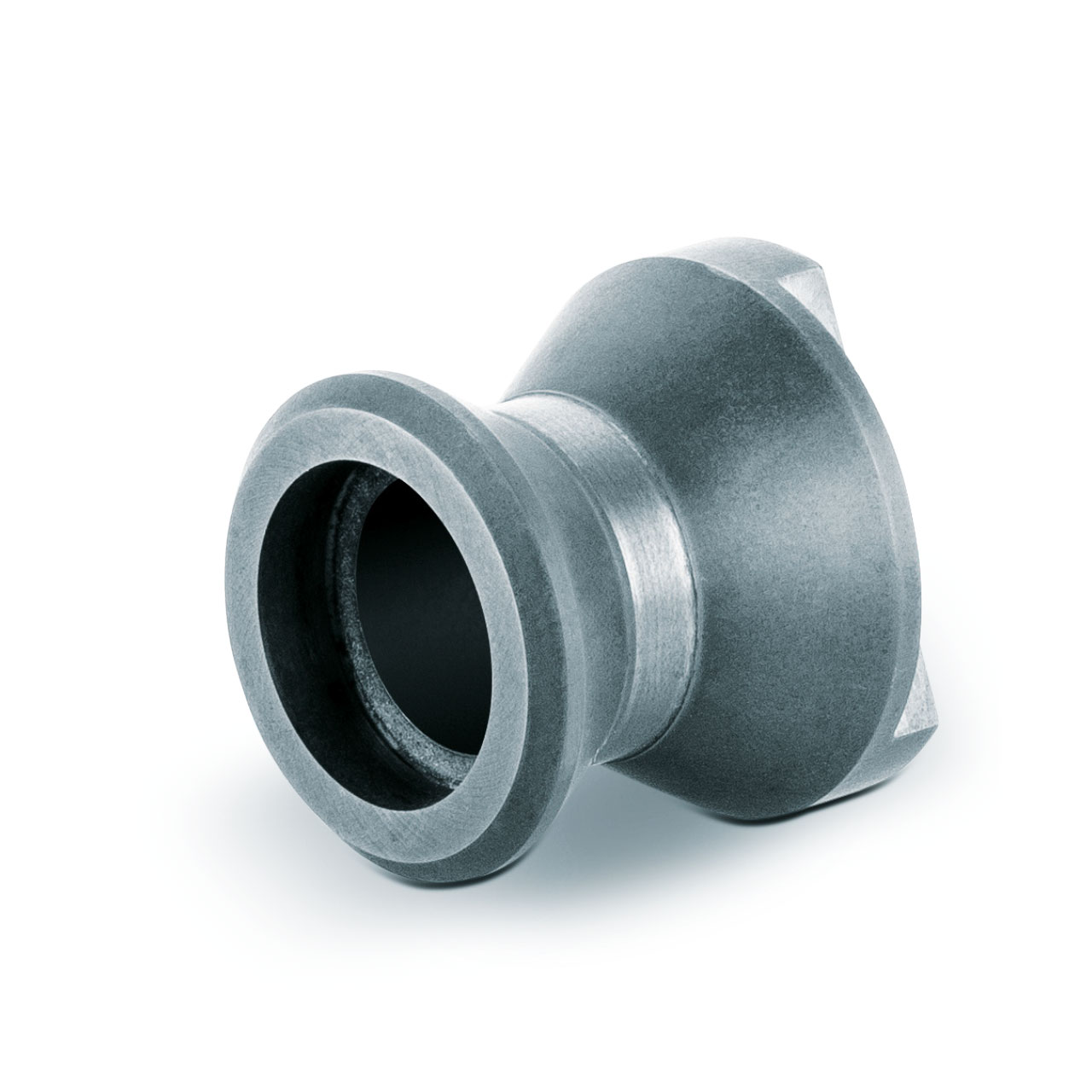

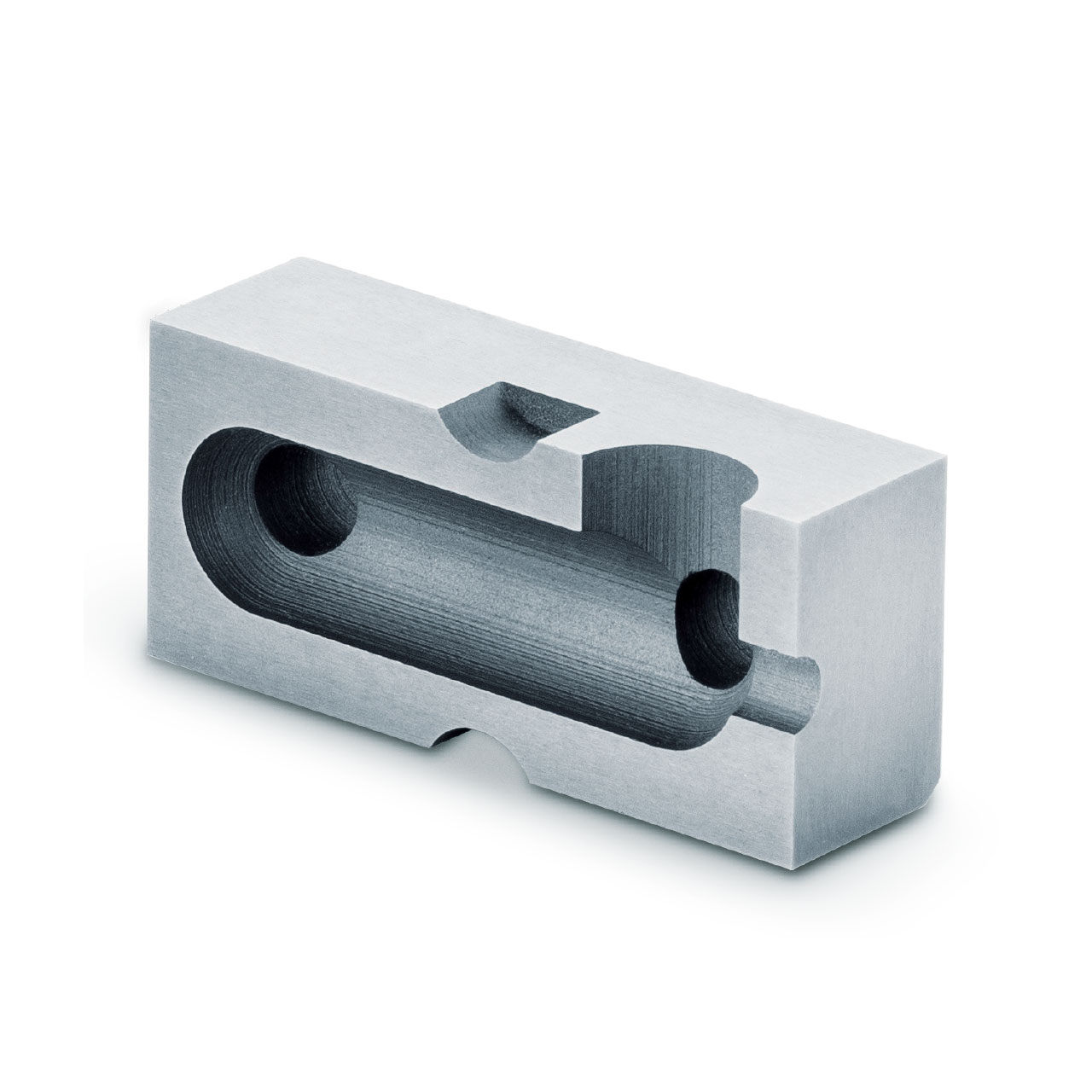

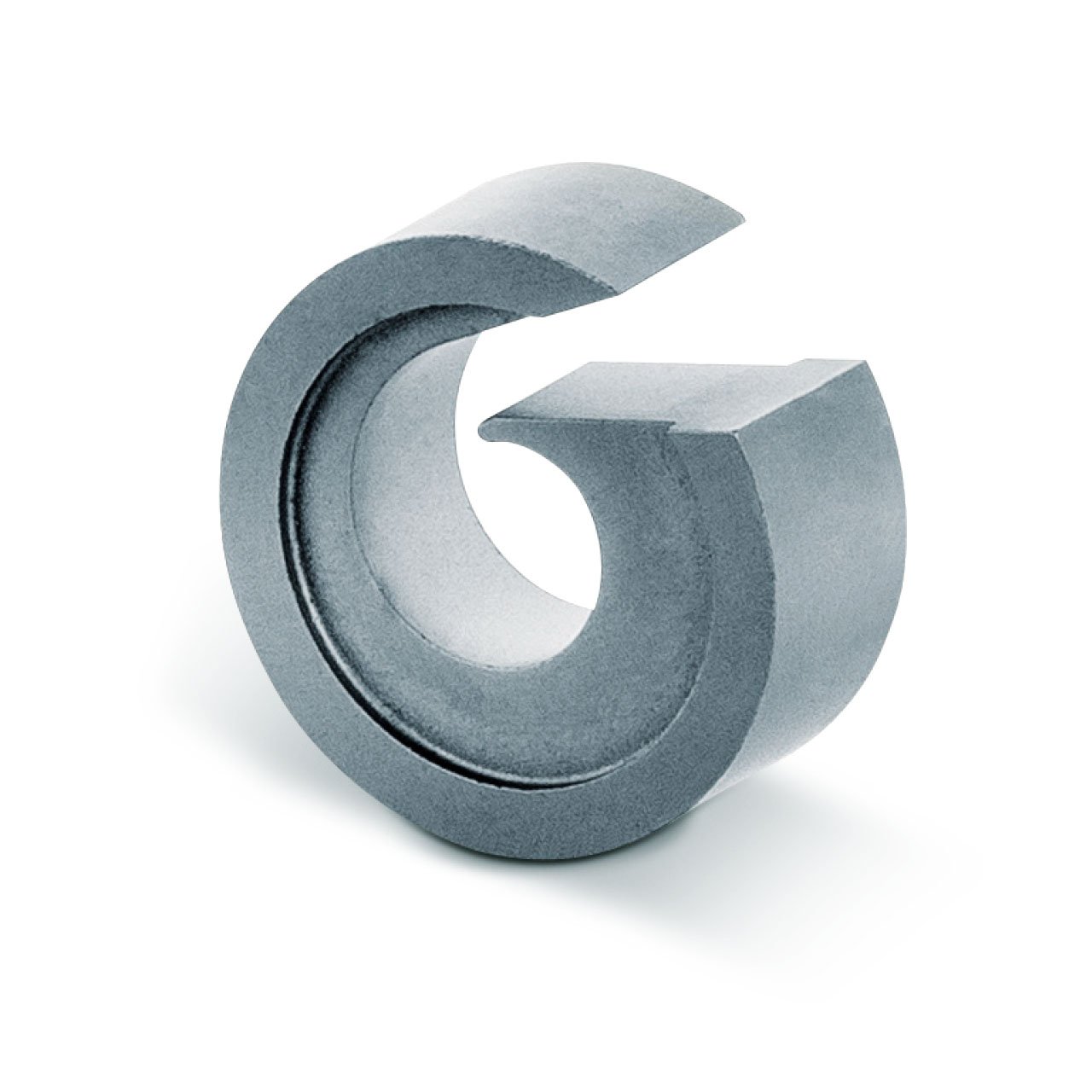

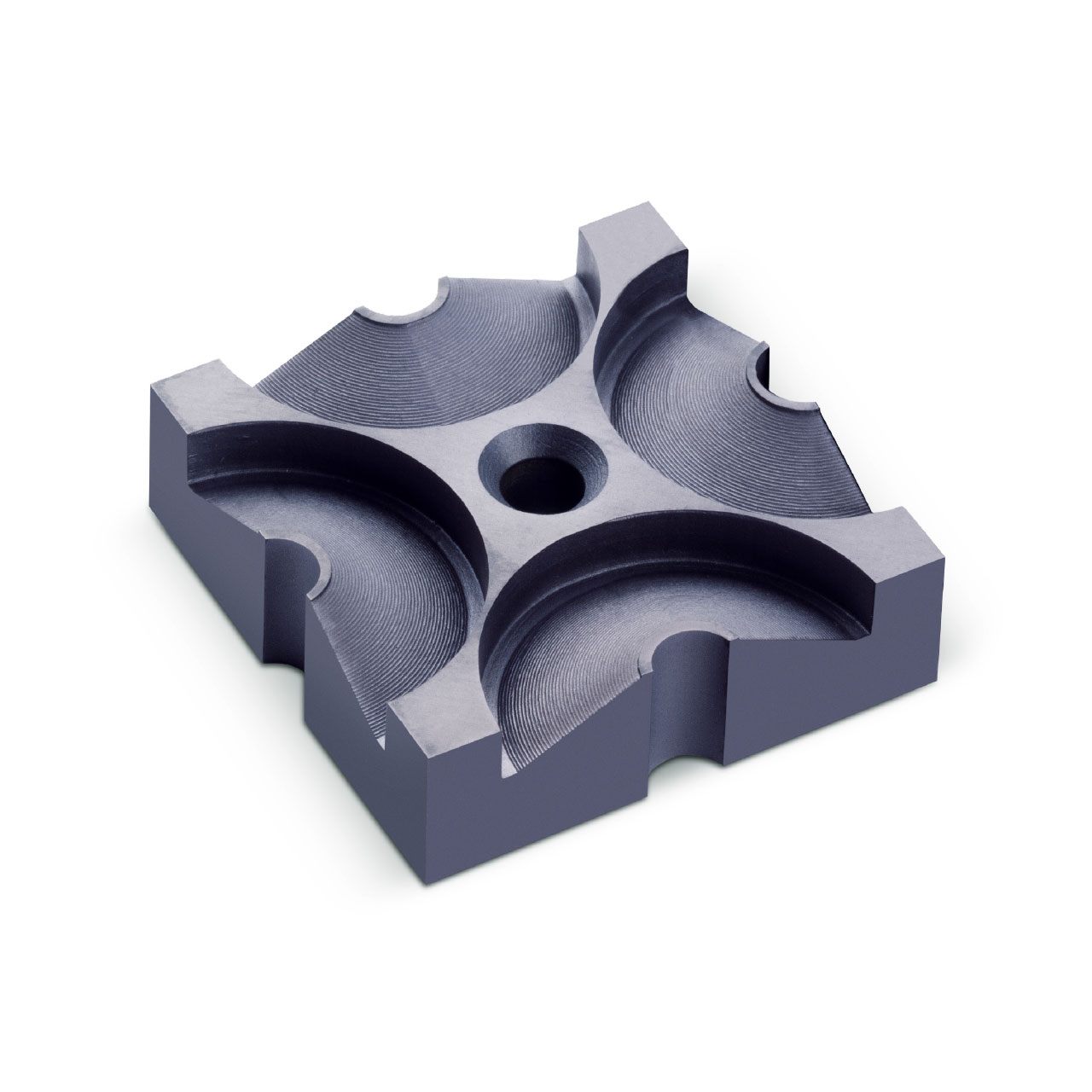

The unique feature of tungsten carbide is that it can be shaped into various forms and sizes. We specialize in making components from tungsten carbide.

Here are a few reasons to consider tungsten carbide parts:

- Scratch resistance

- Twice as hard and dense as steel

- Less wear on the tips and parts made from tungsten carbide.

- Possibility to drill through the hardest of rock faces

- Prolonged use and less downtime in replacing tips and buttons

- Suitable for soft or hard surfaces

- Cost-effective

- Assured performance in the harshest of climates and situations

HIGH PERFORMANCE CARBIDES - MADE IN INDIA

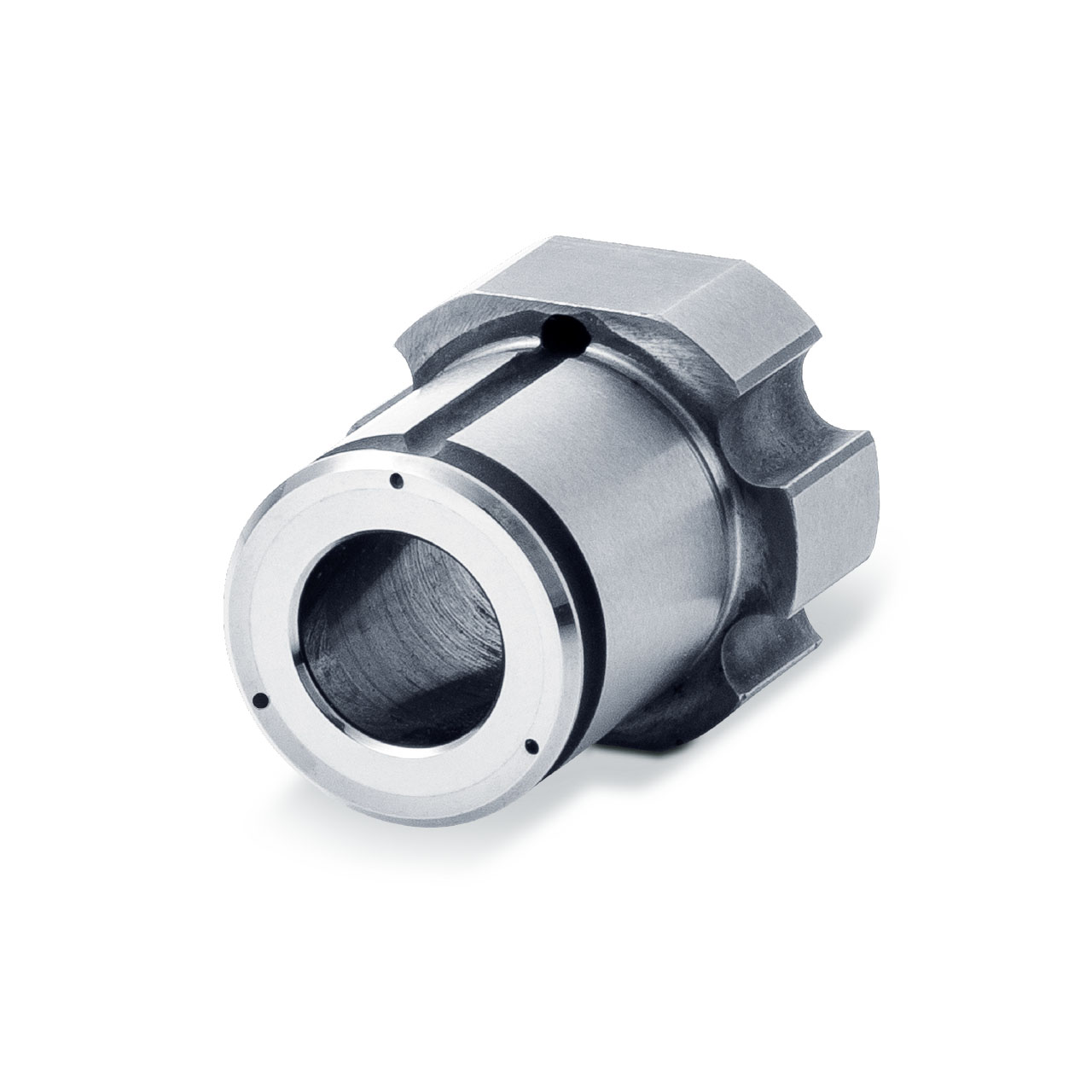

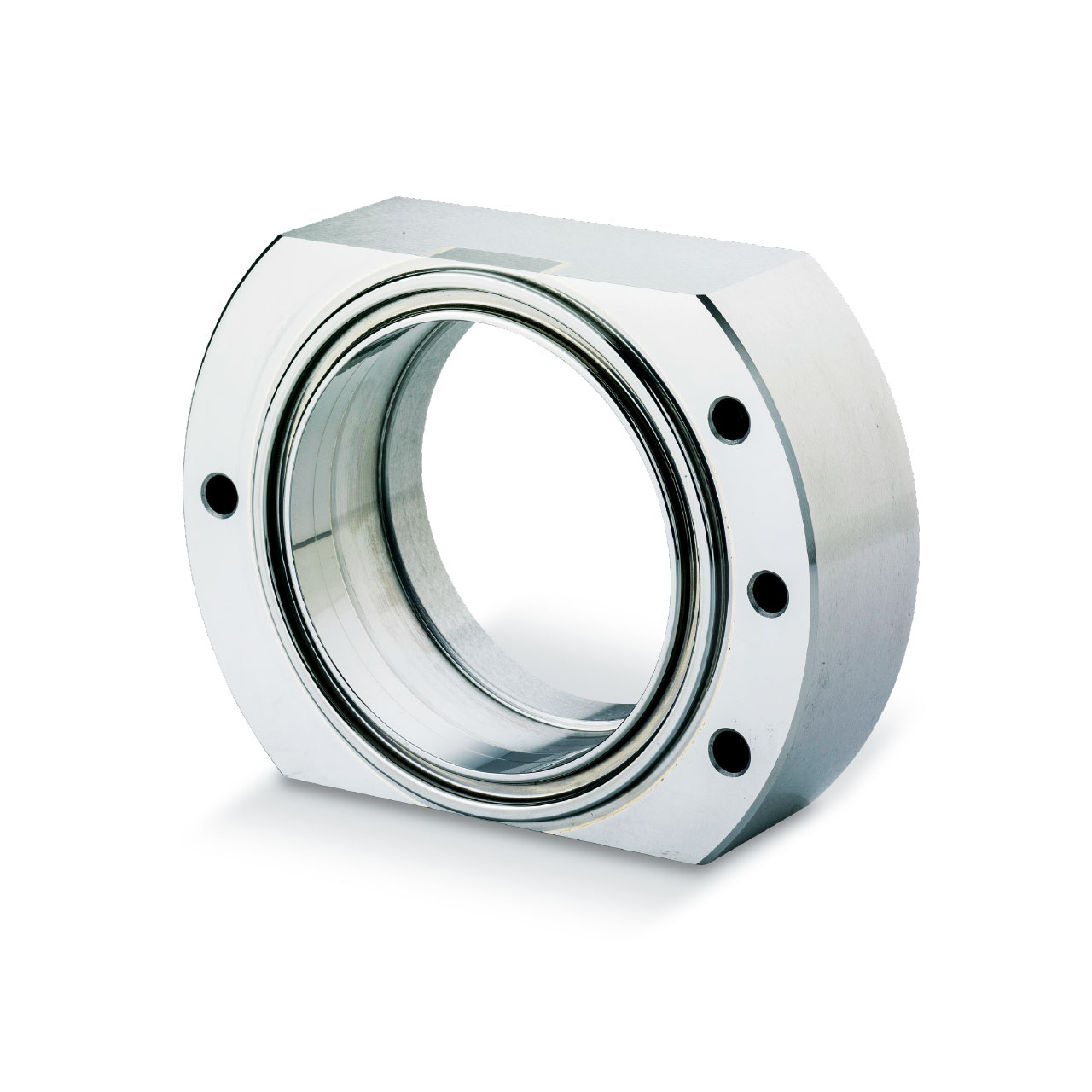

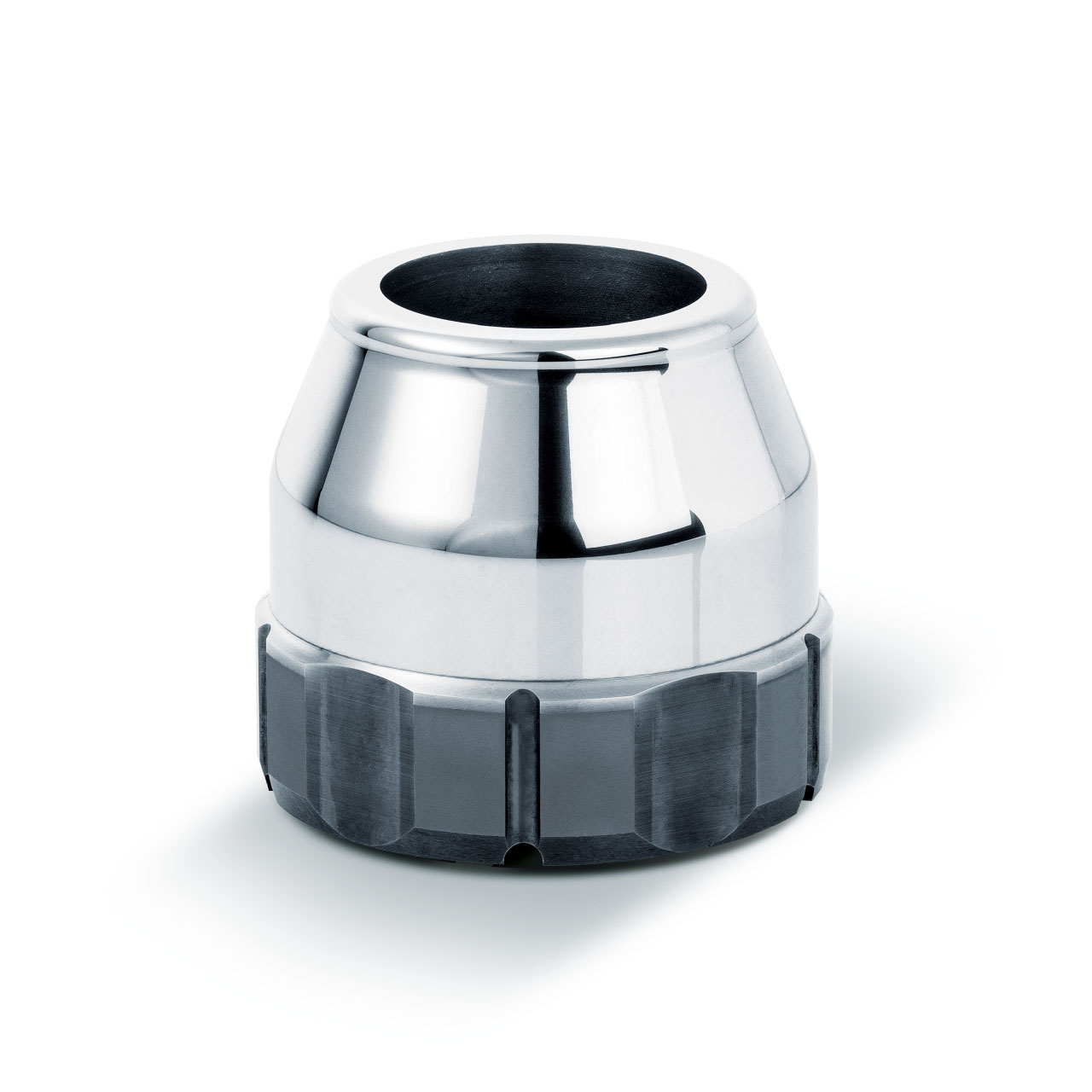

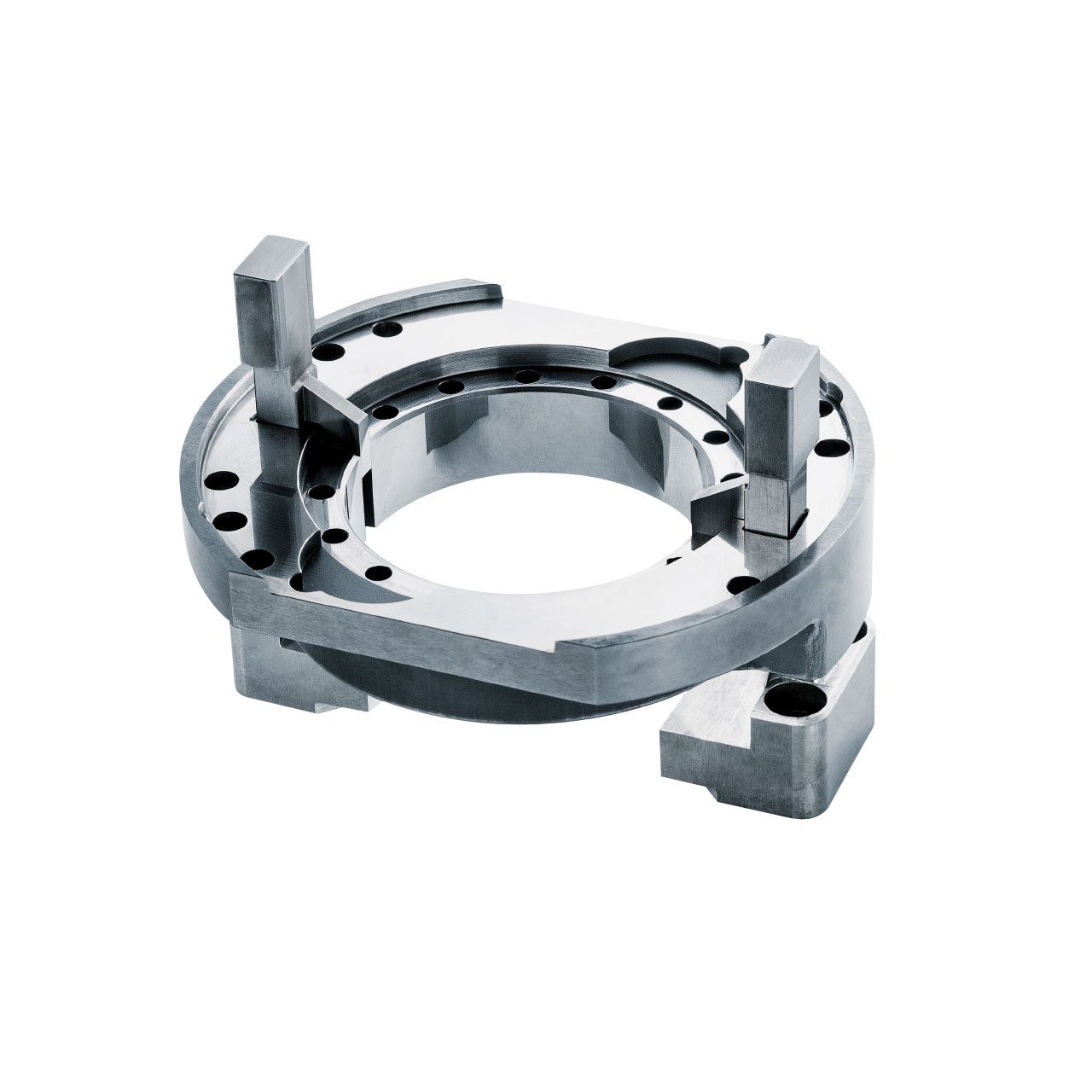

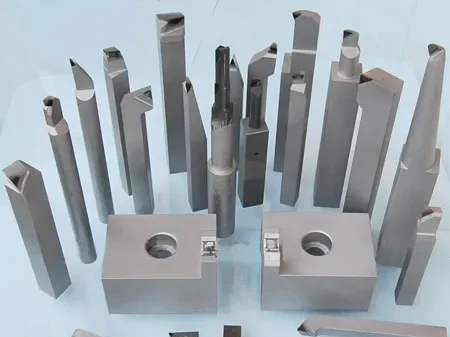

Metalgenesis Industries is a professional supplier of tungsten carbide mould and dies and all kinds of customized tungsten carbide wear parts. We have more than 10 years experience in researching and manufacturing of tungsten carbide products such as carbide molds & dies, bushings, valve seats, nozzles, inserts & cutting tools, carbide rods and bars, carbide plates & strips and other customized tungsten carbide wear parts etc…

Absolutely essential for us is quality on the highest level possible-MADE IN INDIA. Because of that our cemented carbides parts are exclusively produced in order to guarantee the best metallurgical basic for our customers precision tools. We deliver, optimize and refine only premium carbides for industries. Benefit from our first-class quality rods, sintered preforms, and machining services of our high performance carbides.

Quality manufacturing

Because of its extremely high hardness, Tungsten carbide can not be machined by traditional machining process such as turning, milling or drilling. Even Tungsten Carbide can be machined by special tools like PCD tools, CNB tools and Ceramic Tools, but these cutting tools lose the sharpness easily. So we tend to grind Tungsten Carbide with diamond tools or machine Tungsten Carbide by electrical discharge machining(EDM), micro-EDM or by ultra precision wire EDM. We have machines and technologies specifically adapted to machining of Tungsten carbide.

We offer Tungsten Carbide sintered products to various industries, with the primary focus on drilling and mining industry. But expanding our business in the Tungsten Carbide realm, we want to see your drawings. Send us your need and our engineers will provide the solutions for all your manufacturing complications.

Applications of Tungsten Carbide

- Cutting Tools

- Mining Equipment

- Automotive Industry

- Medical Devices

- Aerospace

- Mining

- Mold Parts

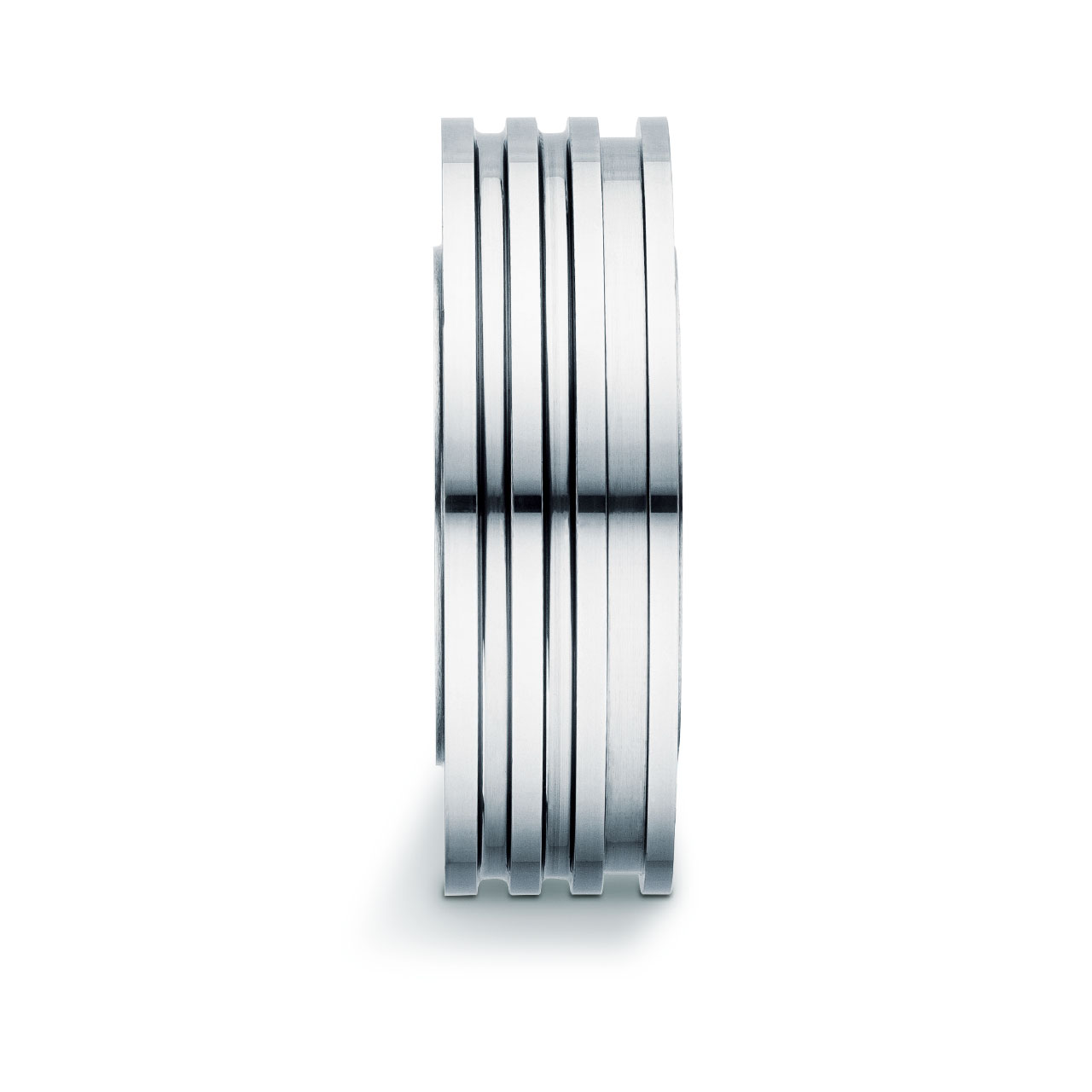

- Jewelry

- Blanks

- Machine Parts

- Industrial Knives

- Blasting and Surface Technology

- Oil Gas Petrochemicals

- Pumps Valves Compressors

- Crushing Milling Pelletizing Recycling

- Conveying Mixing Extruding

- Powder Pressing and Tableting

- Sheet Metal and Metal Packaging

- Cold Heading and Forming Technology

- Drawing Tools

Durable Coatings for Enhanced Longevity

Your product or parts can be strengthened by laser cladding, thermal spray coating, and PVD or CVD technologies, offers boundless possibilities. These wear-resistant coatings embody cutting-edge technological innovation, ensuring an extended lifespan for tools and components.

- Laser cladding

Thick layers.

More wear protection. - Thermal spray coatings

Surface optimization.

Highest wear resistance. - PVD and CVD coatings

Surface refinement and finishing.

Innovative and versatile.

Design And Development

Advancements and emerging trends in wear protection necessitate continuous improvement in the quality of tools and components, which is essential for sustaining the economic efficiency of production and manufacturing processes. In this context, we serve as a trusted and experienced partner, offering expertise in the design, development, and production of specialized tools tailored to customer specifications.

Our customers make progress—partially due to our progressive thinking

When unique requirements for wear resistance arise, or when a production process demands tool materials with enhanced pressure resistance, we are the ideal partner to approach. Our unwavering focus lies in addressing the challenge of wear minimization. The tailored material property profiles of our high-performance materials frequently open up innovative possibilities.

Capabilities

- O.D. Grinding to 300 mm in Diameter- CNC and Conventional

- I.D. Grinding to 250 mm in Diameter- CNC and Conventional

- Surface Grinding to 600 mm Long x 300 mm Wide

- Thread Grinding of Tungsten Carbide, Ceramic and Tool Steels

- Honing – Horizontal and Vertical

- Polishing / Finishing to 0.001 mm (1 microns)

- Lathes – CNC and Conventional

- Milling – CNC and Conventional

- Centerless Grinding

- Single-Sided Lapping

- Induction Coil and Silver Solder Brazing