decanters

Decanter- Repair & Servicing

A decanter can be regarded as a sedimentation tank that is wound around an axis. In the sedimentation tank, the solid particles, which are heavier than the liquid, move to the bottom by gravity and form a sediment (solid phase) at the bottom of the tank.

- When solid/liquid mixtures with a high portion of solids need to be separated, decanter centrifuges are the solution of choice. In contrast to chamber filter presses, these solid shell scroll centrifuges or decanters operate continuously. High centrifugal forces separate the finely distributed solid particles from the suspension.

- We manufacture highly effective products which impress in long-term use with precise and clean cutting edges.

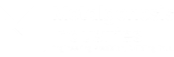

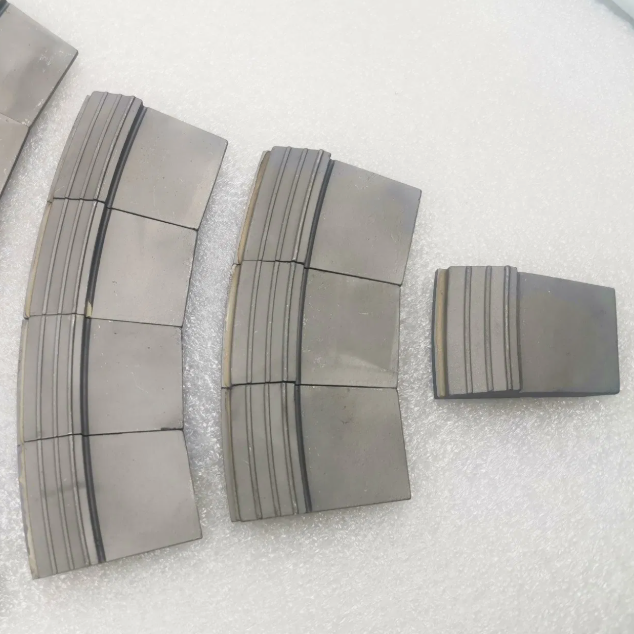

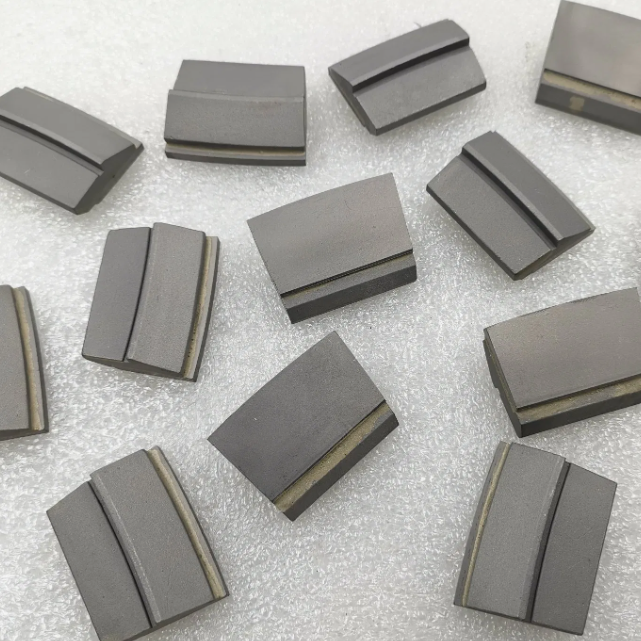

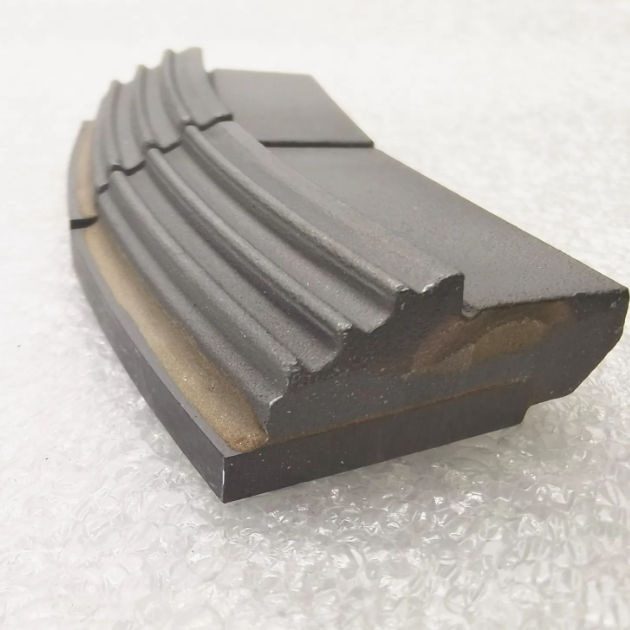

- TC Tile – Tungsten carbide Segment / Plate (3.0 mm thickness) with high wear resistant grade is brazed on Stainless Steel (SS304/316L), EN104405 or Stellite6 steel back plate.

- TC Coating/Cladding – TC Powder spraying on decanter/conveyor flute to increase the wear resistant. – Having limitation of coating thickness up to 0.3 to 0.4mm only, so it gives moderate life.

- TC Liners – TC Tile (brazed assembly) is being welded on decanters and conveyor flutes to increase the wear resistant – This is used for as a screw protection, longer life & easier for replacement. TC Tile thickness is 3.0 mm approx. so it gives good life with comparison to original base steel or Tungsten Carbide Coated flute.