Brazing technology

Brazing technology and specialization -European standards and practices

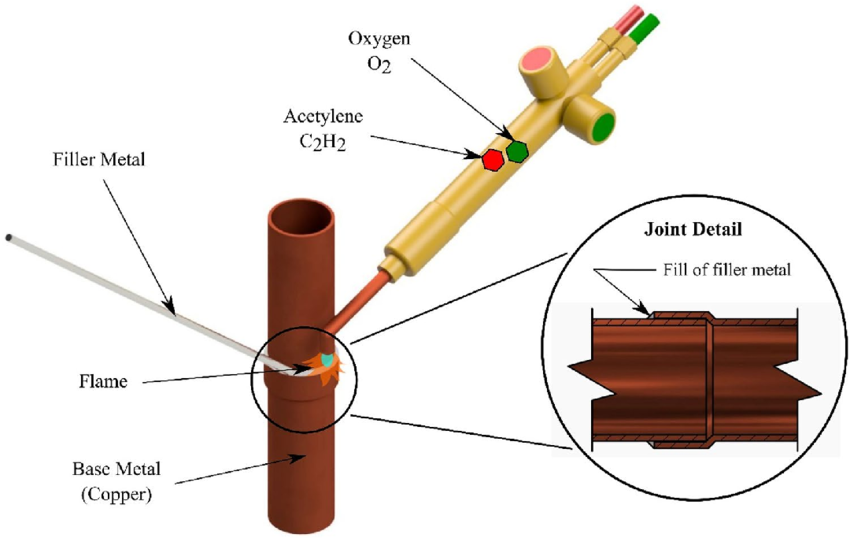

Brazing is a vital metal joining process that uses a filler metal with a lower melting point than the base metals to create strong, durable, and often aesthetically pleasing joints, suitable for various applications including joining dissimilar metals.

Brazing is a joining process wherein metals are bonded together using a filler metal with a melting (liquidus) temperature greater than 450 °C (840 °F), but lower than the melting temperature of the base metal. Filler metals are generally alloys of silver (Ag), Aluminum (Al), gold (Au), copper (Cu), cobalt (Co) or nickel (Ni).

Why Braze?

- Components can be batch processed

- Brazing is production and cost efficient

- Component distortion is minimized or eliminated

- Base metal dilution is low

- Process thermal cycles are predictable

- Joining of dissimilar materials can be achieved

- Thin-to-Thin or Thin-to-thick members can be joined

- Small and wide gap sizes can be filled

- Specialized labor is not required

Advantages

- Can join dissimilar metals, unlike most welding methods.

- High production rates.

- Consumes less power than welding.

- Produces cleaner joints compared to most welding processes.

- Base metals don’t melt, keeping their shape and mechanical properties.

Joint properties

Shear strength – The ability to resist the angular deformation, calculated as the sideways displacement of two adjacent planes divided by the distance between them.

Butt tensile strength – The ability to resist a force applied perpendicular to a given plane without rupturing.

Stress rupture – A fracture caused as a result of repeated physical strain.

Hardness – The ability of a material to resist scratching, abrasion, indentation, or machining, as measured by a specifically chosen method or standard.

Corrosion resistance – The ability of a material to resist attack resulting from environmental, chemical, or galvanic action.

Oxidation resistance – The ability of a material, particularly a metal, to resist reaction with oxygen, which can cause a loss of structural integrity resulting from the formation of undesirable oxide compounds.

Microstructure – The composition and microscopic structure of a material, as studied using metallographic methods.

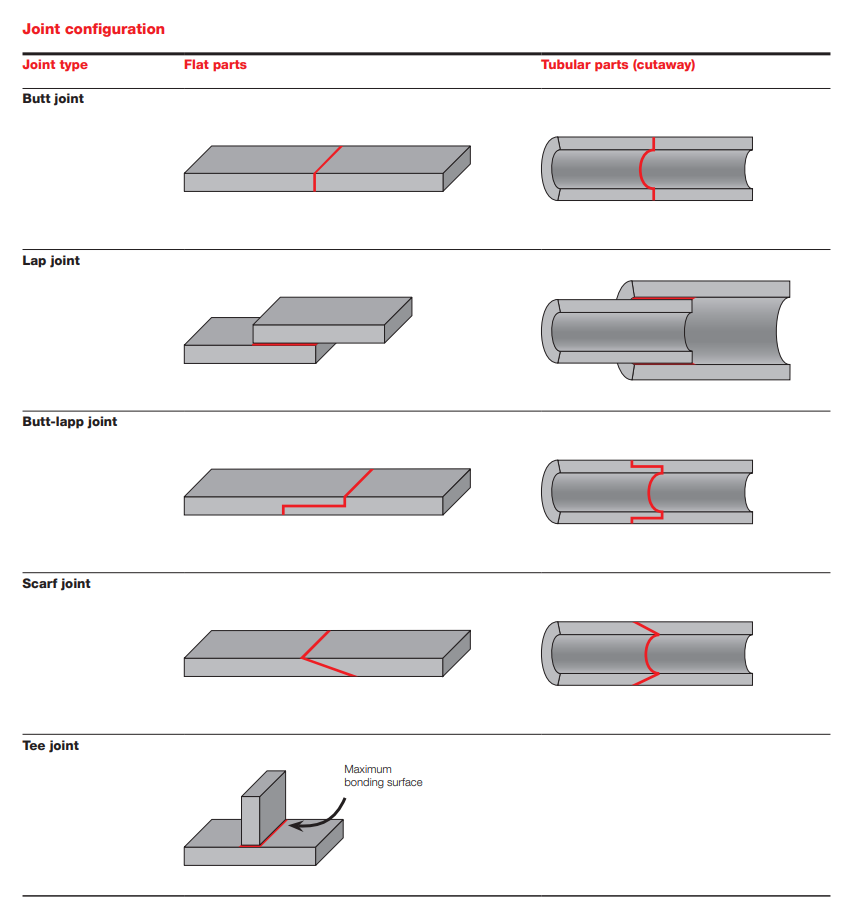

Joint configuration – The design and shape of the joint chosen to join members that will meet or exceed structural requirements in service. Types of joint configurations include lap, butt, tee, tubing, tube thru plate and scarf.

Successful Carbide Brazing with Induction

Tungsten carbide (WC), also referred to as cemented carbide, is a composite material manufactured by a process called powder metallurgy. Tungsten carbide powder is mixed with a binder metal, usually cobalt or nickel, compacted in a die, and then sintered in a furnace. The term “cemented” refers to the tungsten carbide particles being captured in the metallic binder material and “cemented” together, forming a metallurgical bond between the tungsten carbide particles and the binder (WC – Co), in the sintering process. The cemented carbide industry commonly refers to this material as simply “carbide”, although the terms tungsten carbide and cemented carbide are used interchangeably. Carbide exhibits high compressive strength, resists deflection, and retains its hardness values at high temperatures, a physical property especially useful in metal-cutting applications. It provides long life in applications where other materials would not last or would fail prematurely

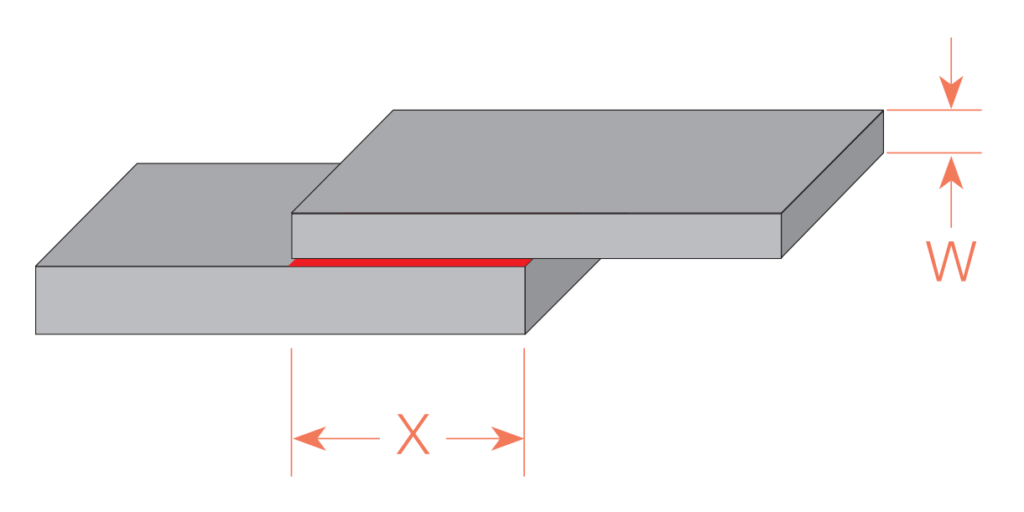

Calculating the length of lap for flat joints

Formula

X = (Y – T – W) / L

Were,

X = Length of lap area

Y = Safety factor desired

T = Tensile strength of weakest member

W = Thickness of weakest member

L = Shear strength of brazing filler metal

Example

What length of lap is needed to join 1.5 mm annealed Monel sheet to a metal of equal or greater strength?

Solution

Y = 2 (desired safety factor for the assembly)

T = 482.6 MPa (tensile strength of annealed Monel sheet)

W = 1.5 mm

L = 172.4 MPa (arbitrary value for the average brazing filler metal)

Result

X = (2 – 482.6 – 1.5) / 172.4 = 8.4 mm (length of lap)