- As machined

- Smooth machining

- Fine machining

- Polishing

- Brushed

- Bead blasted

- Powder coated

- Black oxide

- Electroless nickel plating

- Anodizing

machining

High Precision Machined Parts

We provide versatile manufacturing services

In modern machining practice, harder, stronger, and tougher materials that are more difficult to cut are frequently used. More attention is, therefore, directed toward machining processes where the mechanical properties of the workpiece material are not imposing any limits on the material removal process.

Metalgenesis is also at the cutting edge of technology in this traditional sector. Our range of machinery from leading manufacturers features the latest automation systems and guarantees precision and consistent high quality. From design optimization, including programming, to heat treatment and technical precision cleaning, we cover all stages in the process.

Technology

All the equipment we use for the complete machining of individual parts or assemblies is kept completely up to date and give higher accuracy. Metalgenesis focuses on high-end components, which demand a high degree of precision.

Application

We are proficient at processing a diverse range of materials for a wide variety of applications and industries – providing high precision solutions & precise parts to the Semiconductor, Aerospace, Medical, Automotive, Ammunition and other industries.

Services

- Milling, turning, and rotary milling

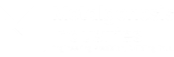

- Wire cutting and die sinking (EDM)

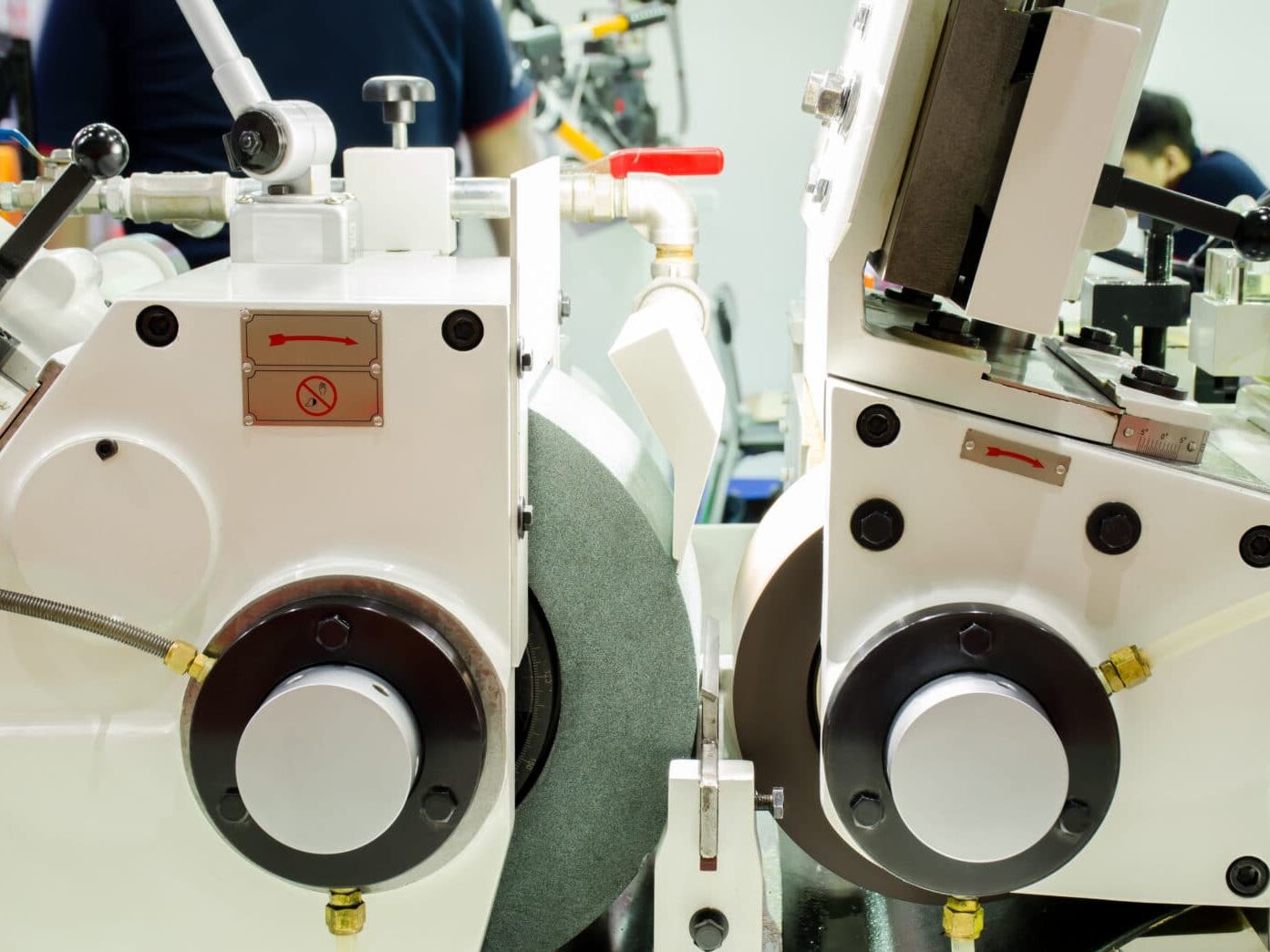

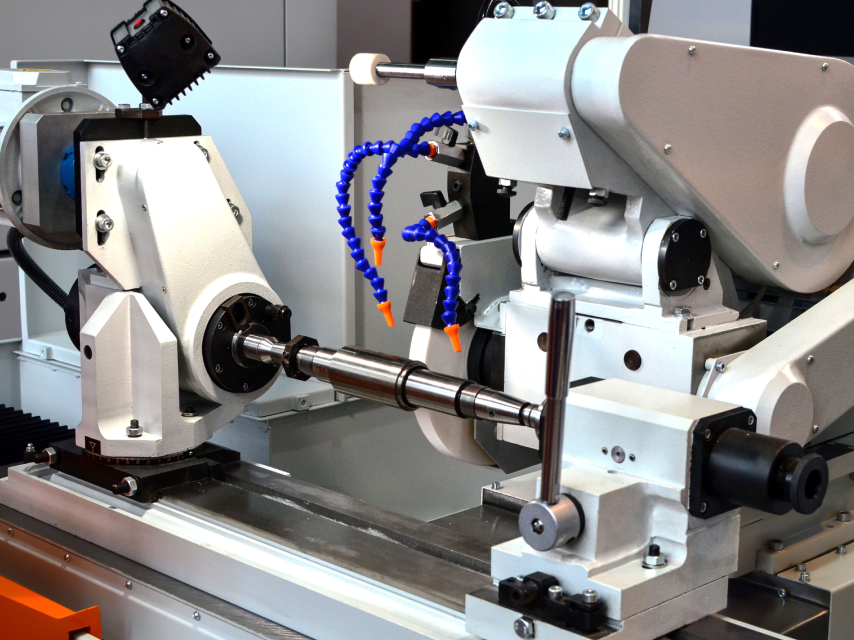

- Flat and cylindrical grinding

- Thermal and surface treatment

- Laser cut and laser marking

- Assembly of components

- Technical cleaning and packaging

- Consistent quality assurance

- Non-destructive surface testing

- Finishing techniques (e.g., lapping, polishing, sand blasting)

- Vacuum furnace

- Welding and brazing

Materials

- Nickel-based alloys

- Titanium and aluminum alloys

- Tool steel and non-corroding heat resist and steel as well as aviation steel

- Mono-crystalline materials

- Tungsten and magnesium

- Tungsten Carbide

- Silicon Carbide (SiC), Silicon Nitride (Si3N4)

- Various grades of stainless steel (203, 316, 304 etc.)

- Different ceramics types (Alumina/Aluminum Oxide (Al203), Zirconia (ZrO2), machinable ceramics

- Plastics- Acrylonitrile butadiene styrene (ABS), Nylon, Polycarbonate (PC), PMMA etc.

Surface finishing service

Cosmetic finishes

Another term for cosmetic finishes could be Cosmetic finishes, decorative finishes or aesthetic finishes, depending on the context. These terms emphasize the visual appeal and polished appearance of the surface. Producing cosmetic parts requires additional measures to minimize defects such as hang marks and scratches from tools.

Metal cutting, or simply machining, is one of the oldest processes for shaping the components in the manufacturing industry. It is estimated that 15% of the value of all mechanical components manufactured worldwide is derived from machining operations.

We are capable of delivering variety of products to customers. Using a range of EDM, Wire cut, Turning, Milling, Surface grinding, cylindrical grinding and CNCs. We machine thin walls, tight tolerances and intersecting intricate features.

Milling

Turning

Surface grinding

Laser cutting

EDM- wire cut

EDM- die sinking

Lapping and Honing

Cylindrical grinding