Mold Making

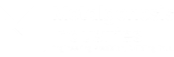

Injection Molding And Mold Making

From micro parts and multi-component injection moulding to customized tools, we cover all steps in the value chain.

We at metalgenesis, provide unique product design & development solutions to customers by giving life to new ideas. We provide realistic, innovative product design solutions by using our in-house Product Designing, Engineering, Tooling & Molding facilities.

Whether you are looking for micro injection-moulded parts produced with absolute repeatability or complex moulded parts featuring uncompromisingly tight dimensional tolerances, our system solutions precisely and reliably meet your requirements across all steps in the process.

We will work with you from the initial quotation all the way through the delivery of your parts to ensure that you’re pleased with our service.

What we provide?

- Injection Mold Design

- Compression Mold Design

- Transfer Mold Design

- Thermoform Tooling Mold Design

- Overmoulding Mold Design

- Unscrewing Mold Design

- Gas-assisted Injection Mold Design

- Hot Runner Mold Design

- Mold Design with Complex Actions

- Prototype Mold Design

- Interior Trim Mold Design/ Exterior Trim Mold Design

Technology

Today designers and engineers readily turn to plastics because they offer combinations of properties not available in any other materials. Plastics offer advantages such as lightness, resilience, resistance to corrosion, color fastness, transparency, ease of processing, etc., and although they have their limitations, their exploitation is limited only by the ingenuity of the designer.

Our expertise ranges from commodity thermoplastic resins to high-temperature materials. From insert to multi-material moulding. This is complemented by versatile surface techniques – such as printing, painting, or laser marking. From the manufacturing and measuring of electrodes to wire cutting and die sinking to the complete machining of inserts and mould bases our mould making services are available exclusively too.

Materials

All standard commodity and engineering thermoplastics

- High-temperature resins, such as PEEK, PPSU, PPS, etc.

- Thermoplastic elastomers (TPE)

- HDPE and LLDPE

However, the list doesn’t end here. There are a variety of materials available. That’s why choosing the right plastic material for your custom injection molding project is an important decision.

In the field of mould making, we process:

- Tool steel

- Stainless and acid-resistant steel

- Hard metal/Tungsten copper

- Copper and brass

Services

- Tool design

- Tool making

- Complex insert applications

- Delicate small and micro parts with high-quality finishing

- Clean room solutions

- Multi-component injection moulding

From design to production – we take care of it all

Application

Our full range of solutions includes small and micro moulded and injection moulded parts used in areas including medical and automobile sectors.

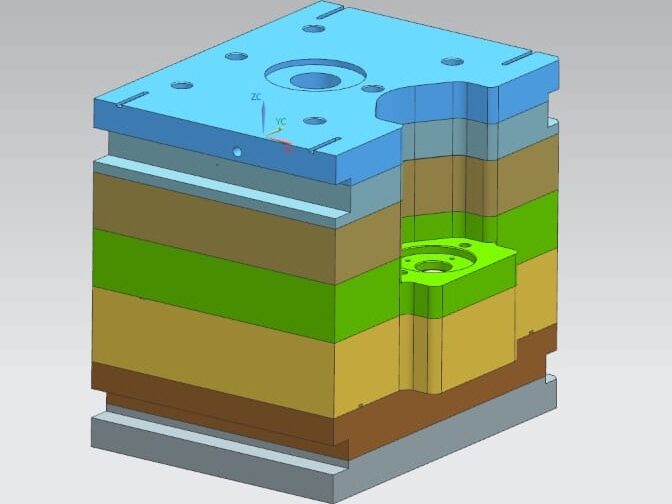

Die Casting Mold

Realize your different type of casting requirements like Die casting, Investment Casting & Sand Casting for different materials like Cast Iron, Cast Steel, Cast Aluminium, Brass, Zinc Nickel etc.

Die casting design requires precision and technical skill. We will find this conjunction with the best services to develop the best components for your products. A deep knowledge and a lot of experience is essential components to obtain high-level results using the best zinc die casting technologies.

Discover our services and applications.

Powder Compression Dies

We regularly manufacture dies made from Hardened Alloy Steel for all Powder Compaction Applications. Simple or complex, we have the experience it takes to manufacture all shapes and sizes of compression tooling.

Hardened Alloy Steel Dies are preferred for all applications where use of tungsten carbide is not essential. We use the highest quality materials to create efficient, durable and highly performing tooling.

Dies made from Hardened Alloy Steel achieve a high hardness & hence take high pressure. Also, this material is corrosion resistant. Each die consists of two-piece outer die body, punches (anvils), pusher rod & pellet removal ring. Die is fitted with a vacuum nozzle for evacuation (if required). Both punches (anvils) have one face mirror finished, which ensures excellent surface finish of pellets.

Die can be easily dismantled for cleaning purposes. The entire set is enclosed in a wood box for safety & durability.

Our punches and dies:

- Are designed for maximum tool life

- Can be customized to meet the exact requirements of your products and process

- Ensure consistent operational efficiency and high product yield

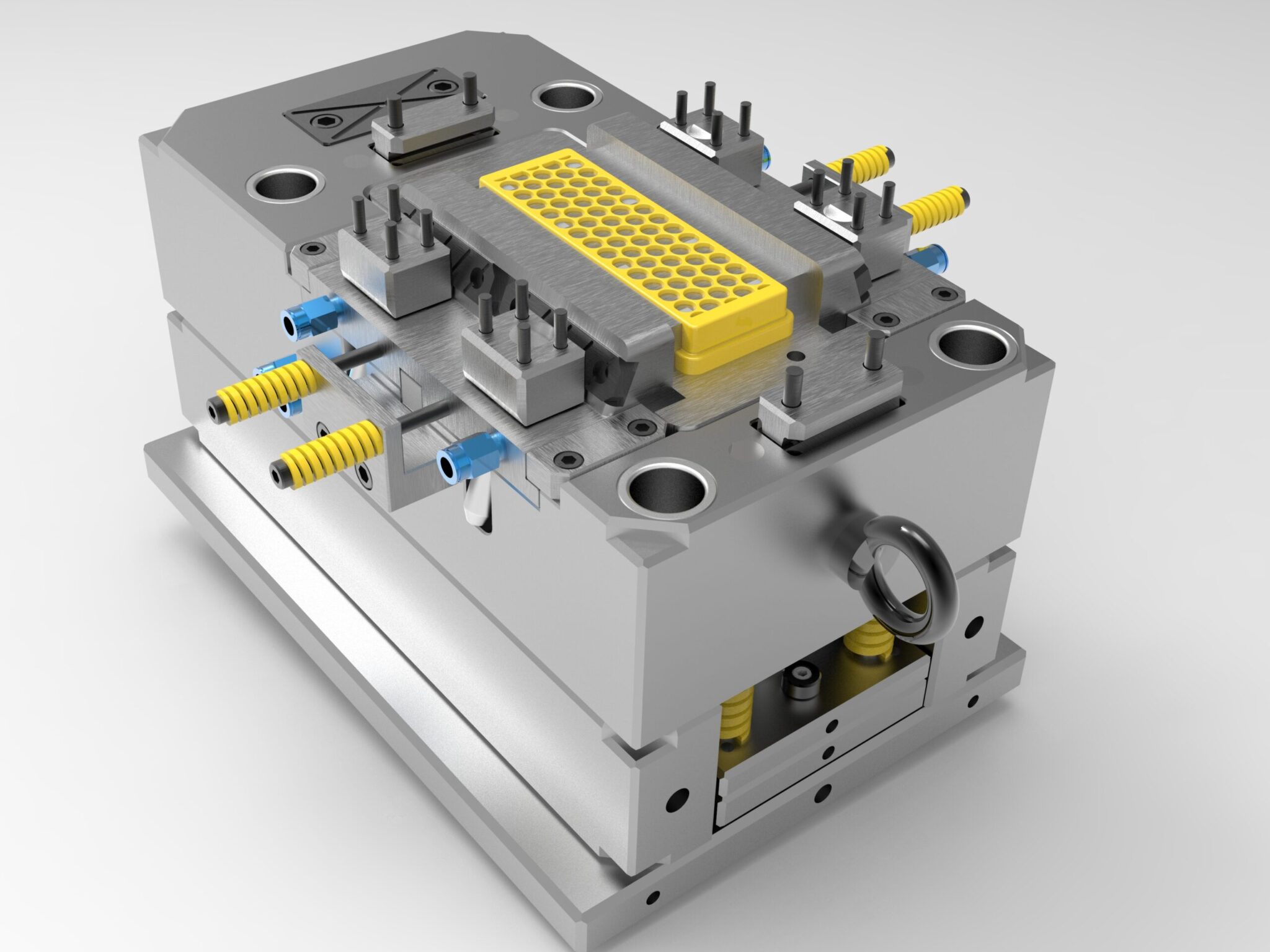

Box Injection mold

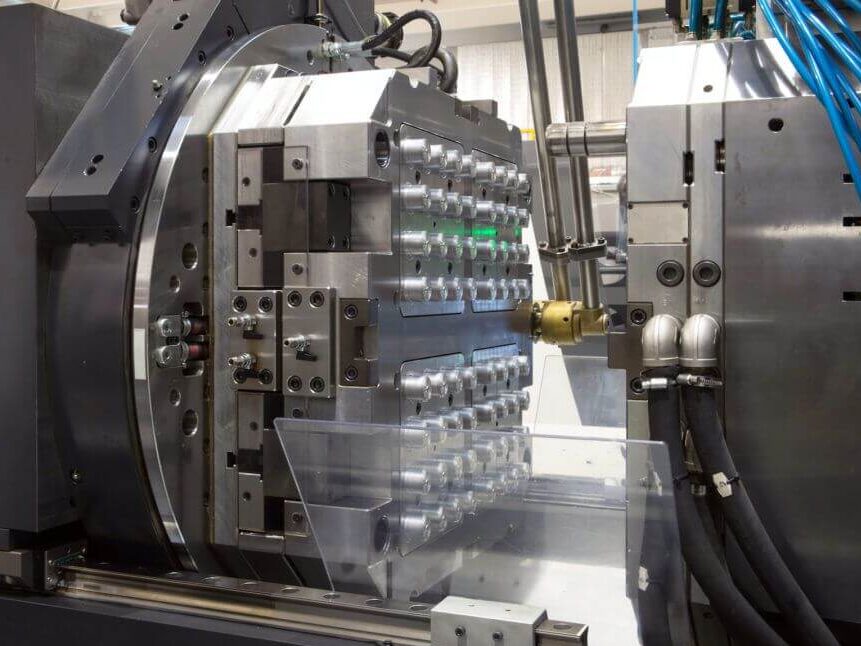

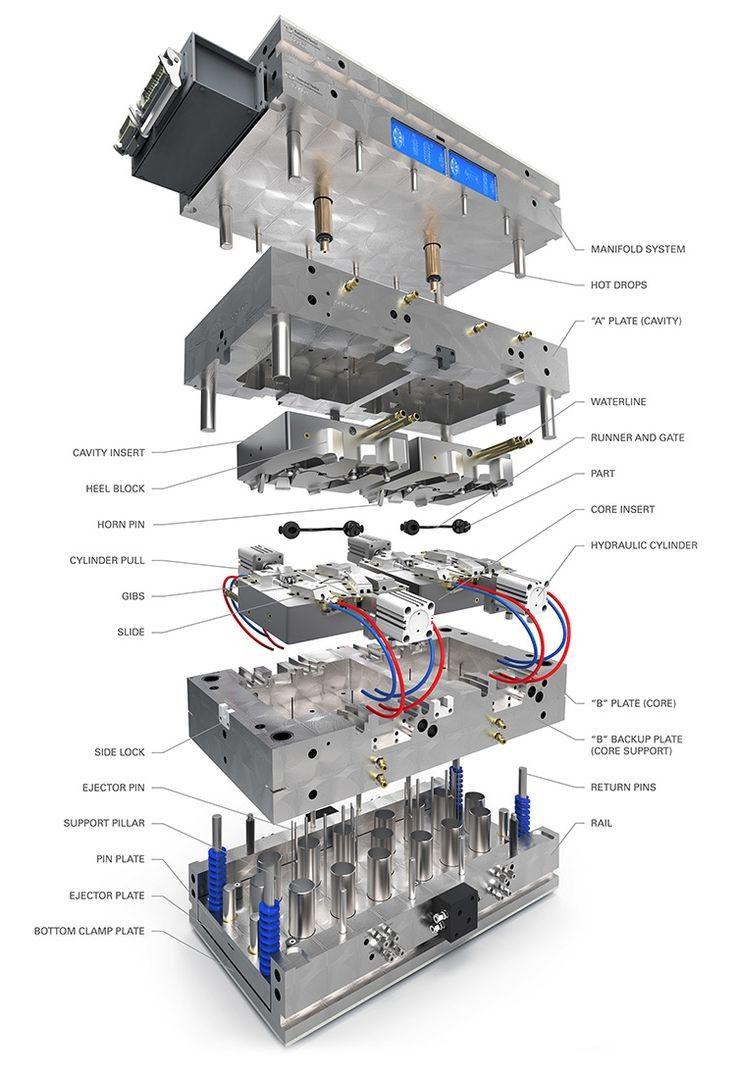

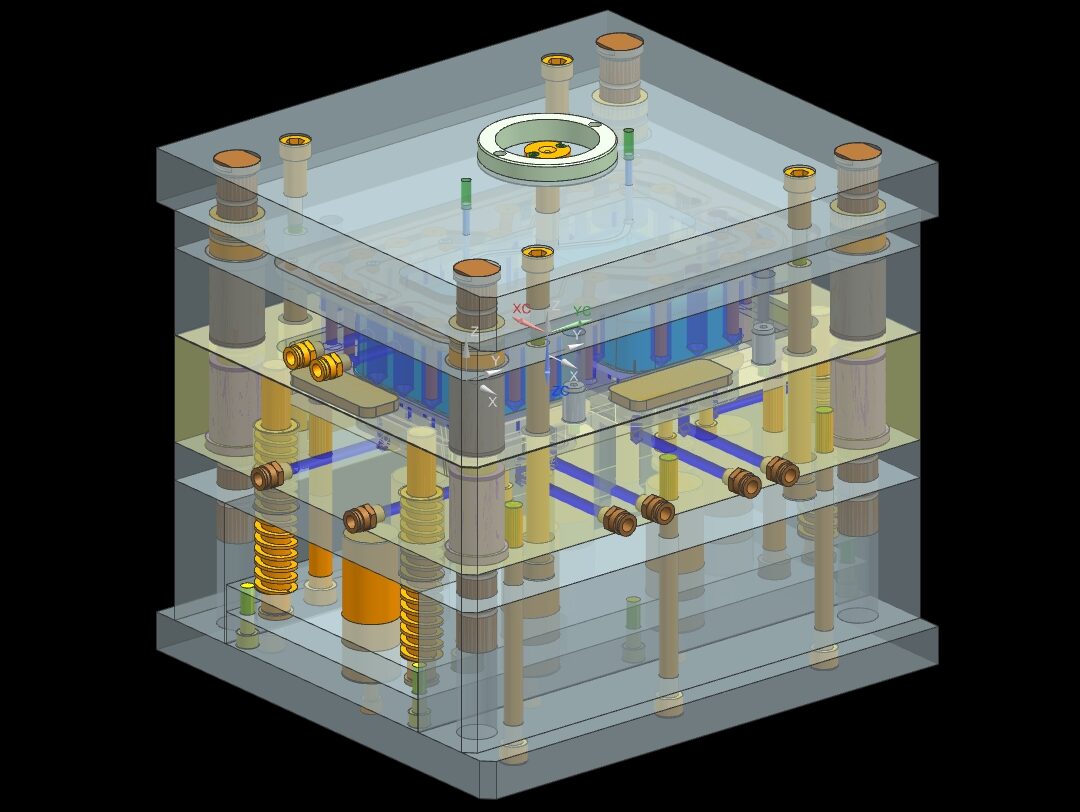

Injection mold design

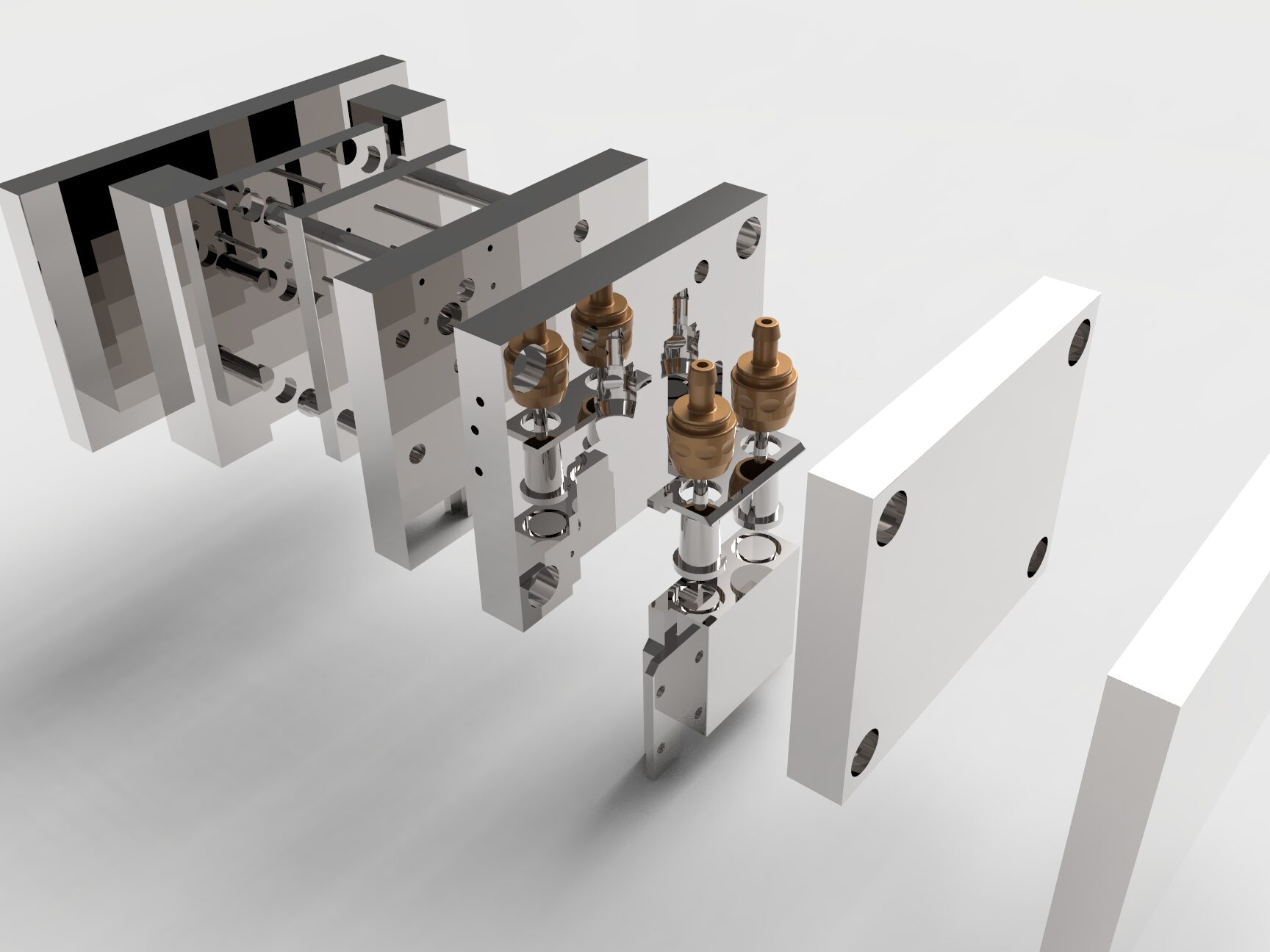

Mold exploded view

Plastic mold parts

Compression dies

Tablet punches

Rotating punches