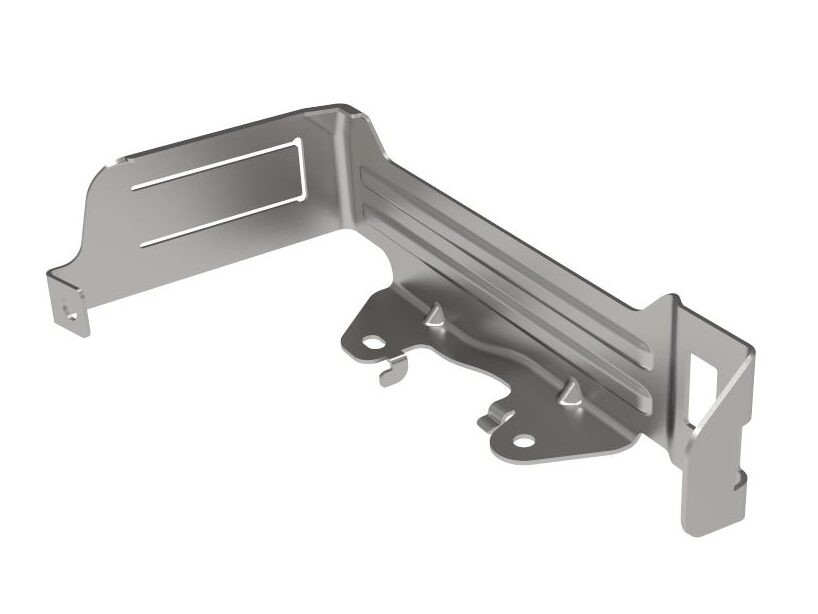

sheet metal

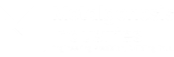

Sheet Metal Stamping And Tool Making

We are manufacturers of precision press tools, pressed sheet metal parts, and sheet metal fabrications. Our quality and deliveries have been well recognized by all our customers.

We provide realistic, innovative product design solutions by using our in-house Product Designing, Engineering, Tooling & Stamping facilities.

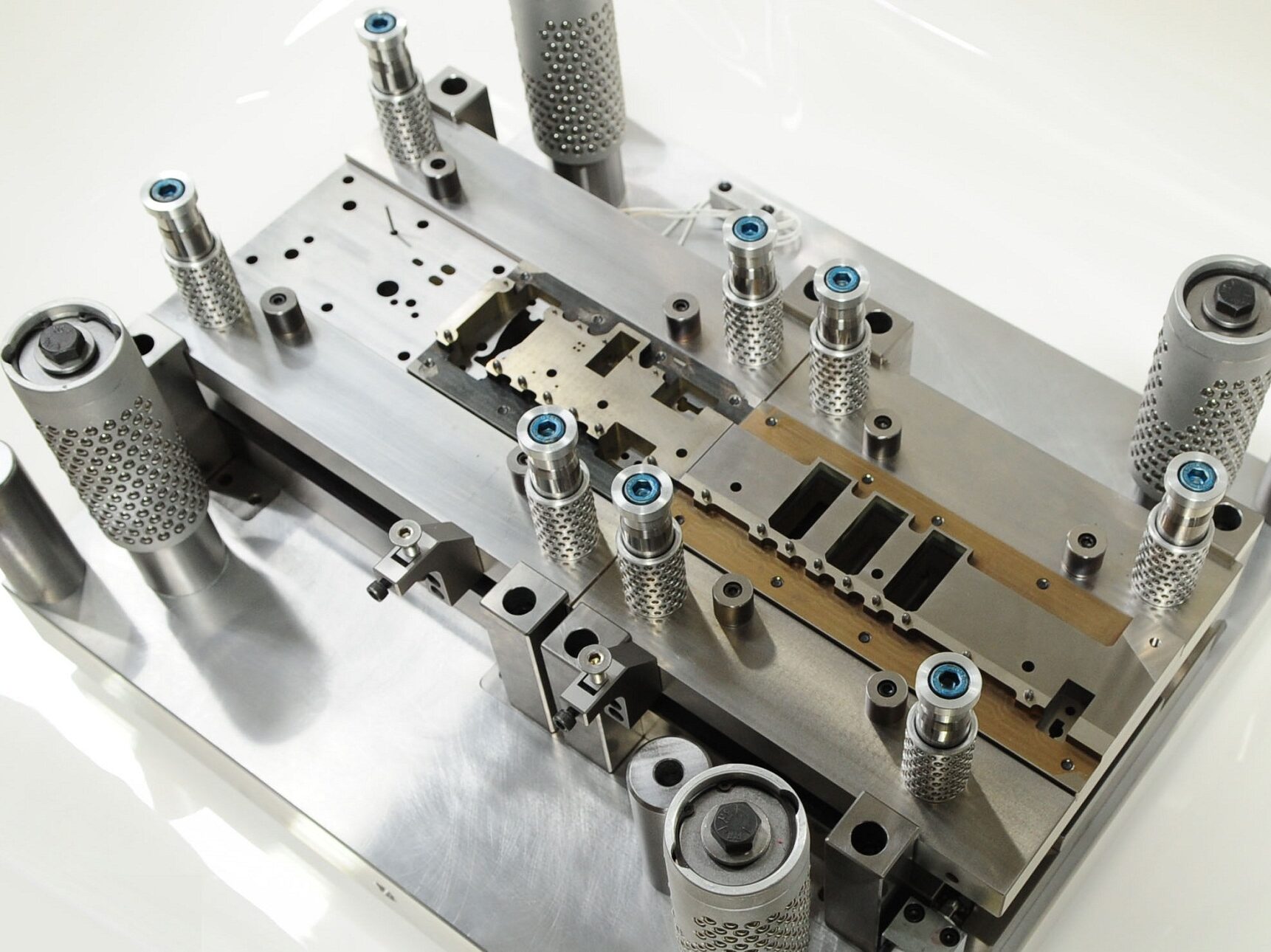

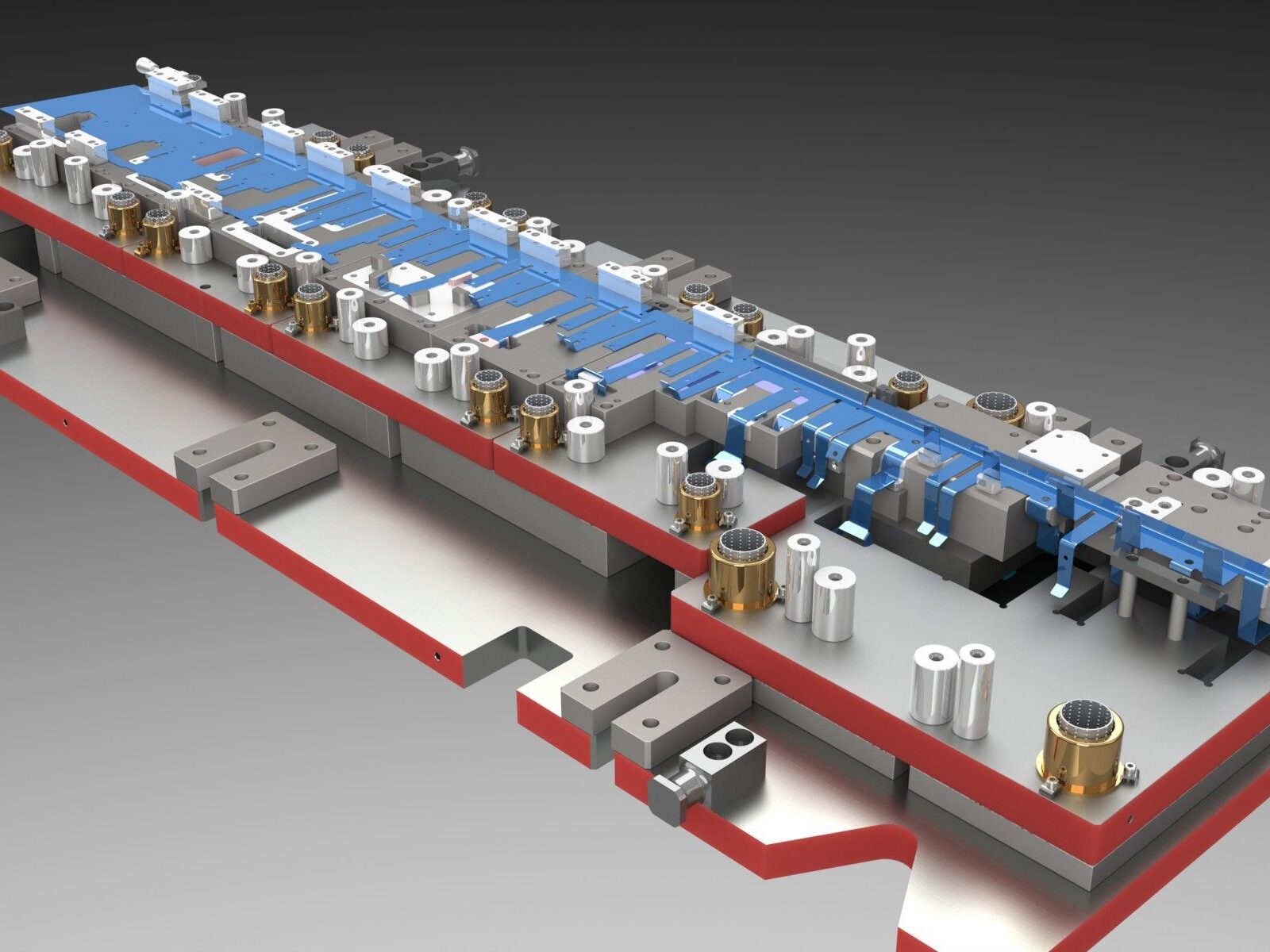

We provide design support to manufacturing companies by providing high end design consulting. Over the years we specialized in providing Detailed 3D Model based designs which are manufacturing proven by process validation using high end simulation technologies.

We assist you in determining the feasibility of your design and addressing any vulnerabilities or flaws.

We also work on tool manufacturing and part production to ensure your press tool services reach completion without bottlenecks or time lags.

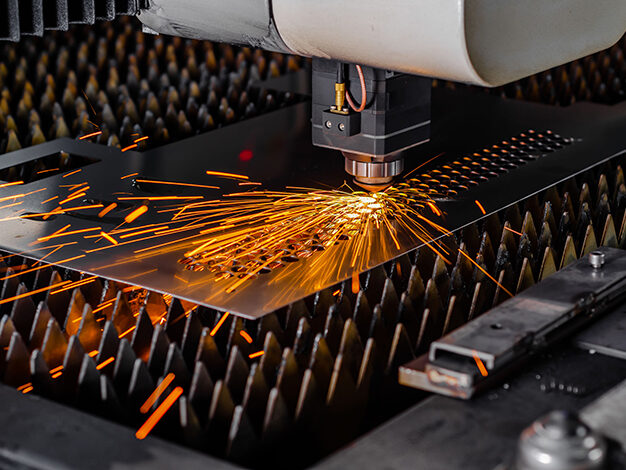

Technology

From the designing and manufacturing of stamping tool to the complete production of the part our stamping services provides you with a complete solution.

Application

Our expertise ranges from stamping thin sheets for electrical sectors to thicker sheets for automobile use.

We are manufacturers of precision Press Tools, Pressed Sheet Metal Parts, and Sheet Metal Fabrications. Our quality and deliveries have been well recognized by all our customers.

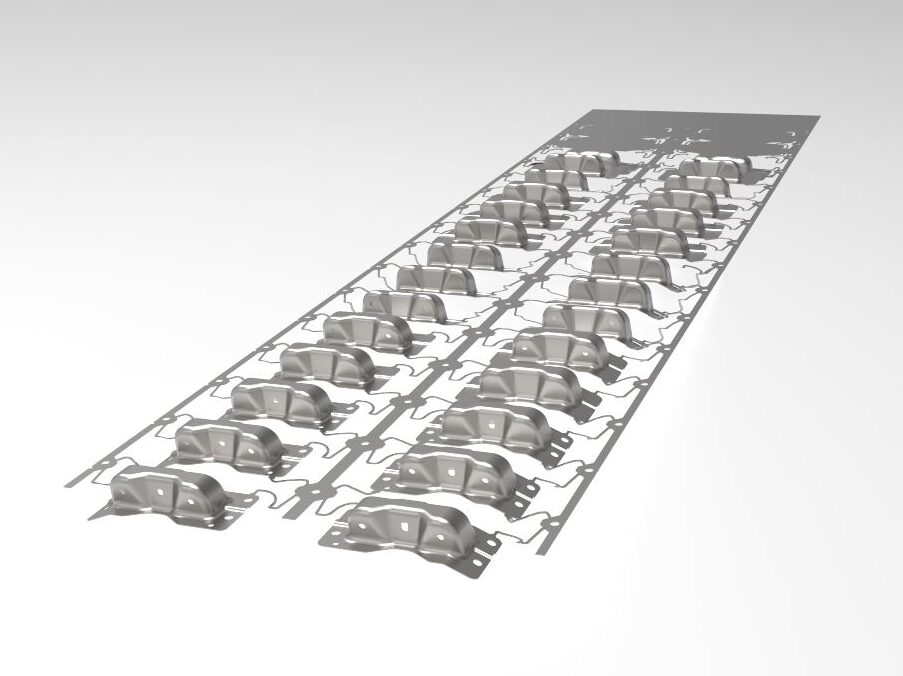

A well designed and built Press tool can help you improve quality as well as efficiency. Since these dies can perform several operations in sequence, they minimize both the chance for error and the person-hours required to make a part.

Materials

- All standard commodity and engineering materials

- Carbon steel, alloy steel, and stainless steel.

- Aluminum alloys

- Brass alloys

- Copper alloys

- Nickel alloys

In the field of tool making, we process:

- Tool steel

- Stainless and acid-resistant steel

- Hard metal/Tungsten copper

- Copper and brass

Services

- Tool design

- Tool making

- Part production

- Stamping die-sets

- Complex insert tooling

- Delicate small and micro parts production

- Clean room solutions

- Progressive/single stage component production facility

From design to production – we take care of it all

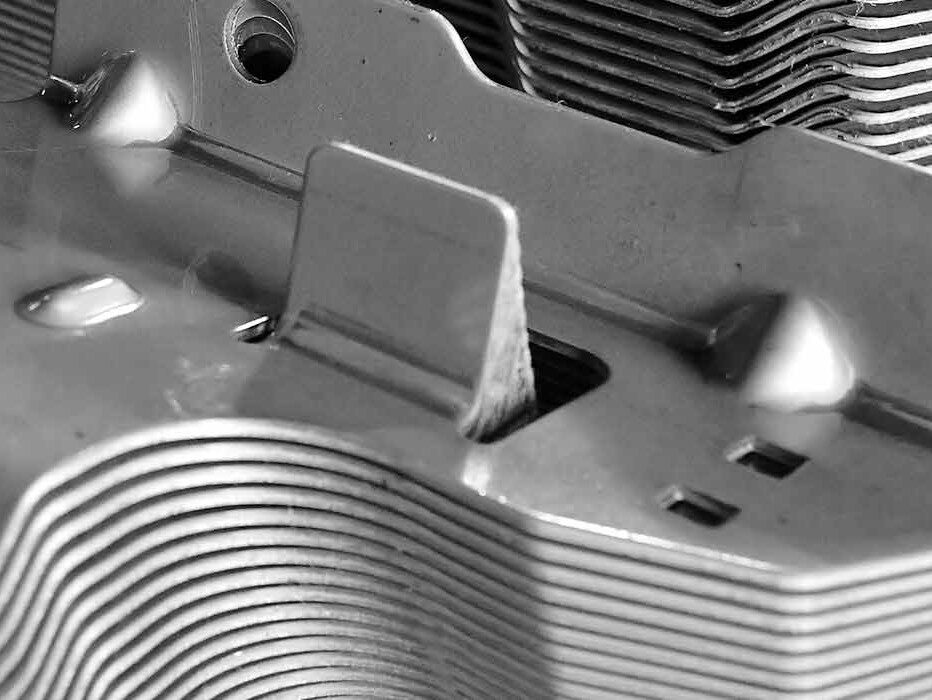

Quality manufacturing and production

All production tooling undergoes a Preventative Maintenance program. All tool maintenance, repair, Engineering Change, and VA-VE activity is carried out on site with full design control and no interruption to customer deliveries.

A well designed and built Press tool can help you improve quality as well as efficiency. Since these dies can perform several operations in sequence, they minimize both the chance for error and the person-hours required to make a part.

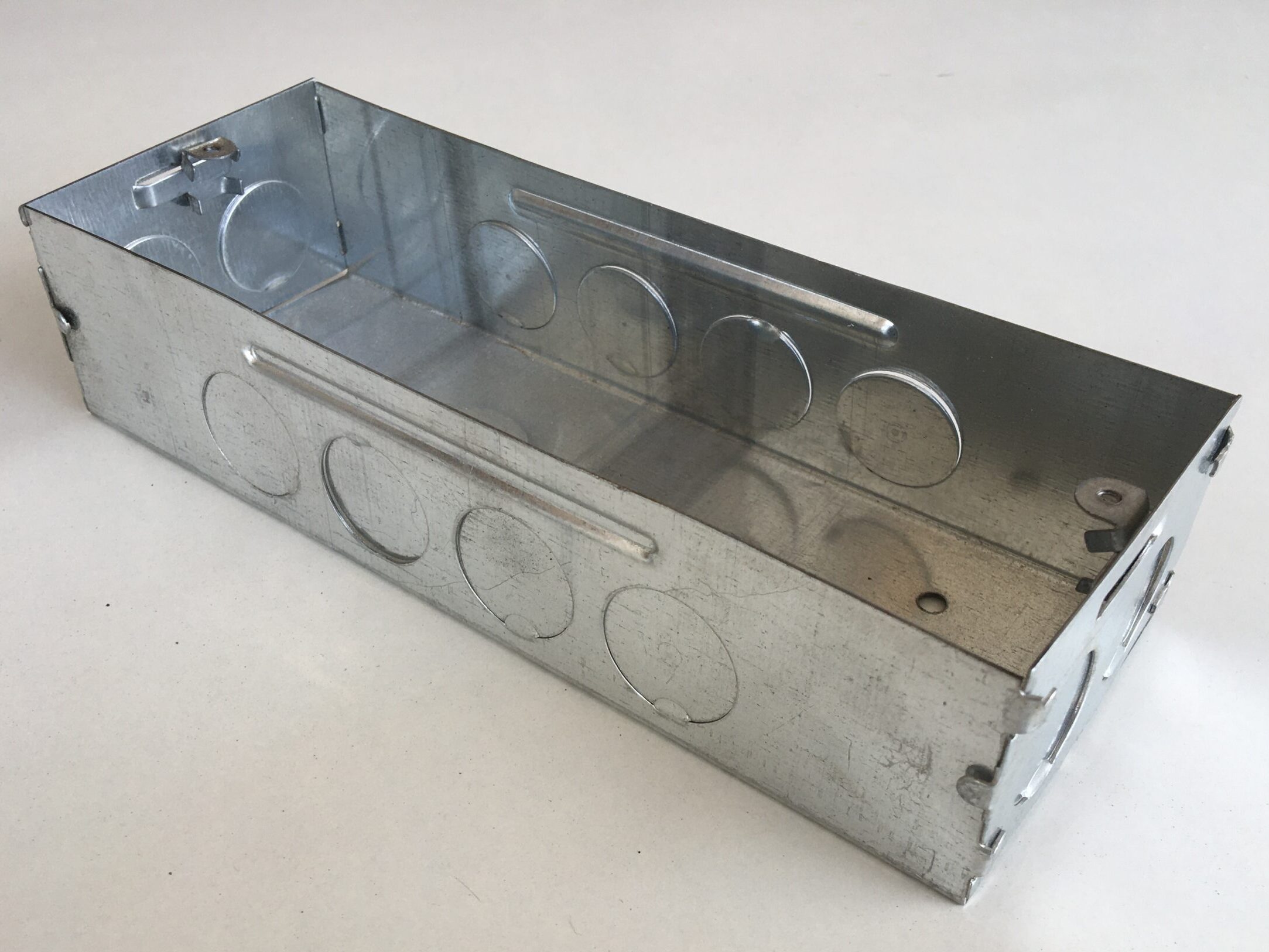

Drawing part

Progressive layout

Press part